5

37

503 97 64-01

503 80 17-01

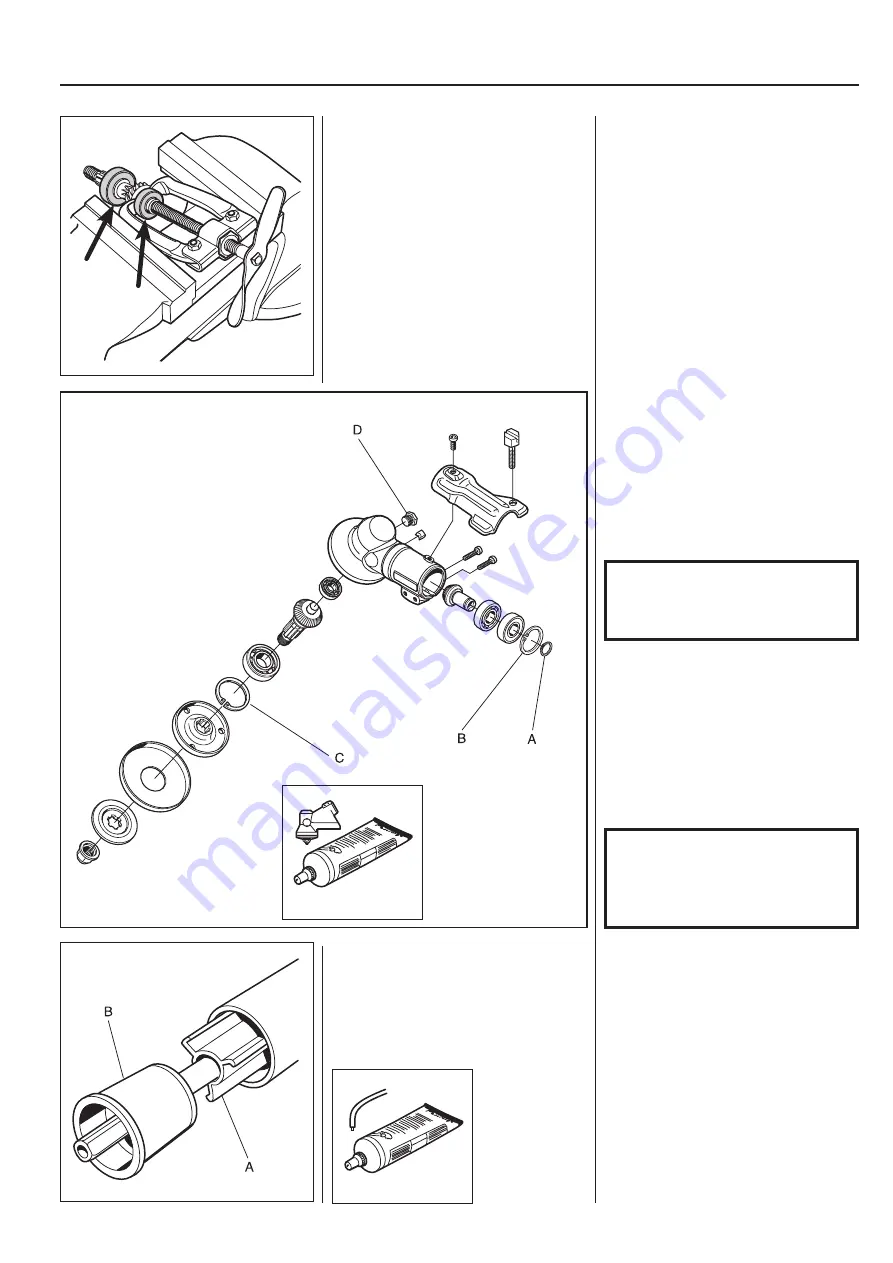

Angle gear

Dismantle the bearings from the output

and input axles.

Dismantle the bearings from the output

and input axles with the help of a small

bearing puller.

TIP!

Hold the bearing puller in a vice so that it

gains a better grip around the bearing.

NOTE!

Do not forget to fi ll the gear

housing to approx. 3/4 with gear

housing grease 503 97 64-01 once

the plug (D) has been removed.

Assembly

Clean all component parts and replace if

damaged or worn.

Fit the bearings on respective axles. This

is easier if the bearings are heated to ap-

prox. 110°C using a hot air gun.

The bearings on the input axle are sealed

on one side. Turn the bearings so this

side faces outwards.

Heat the gearbox to approx. 110°C and

fi

rst place the output axle in position and

then the input axle.

Make sure the bearing bottoms in its

seating.

Fit the circlips (B) and (C). Make sure they

lie correctly in their grooves.

Assemble remaining parts in the reverse

order as set out for dismantling.

NOTE!

Do not forget the circlip (A)

holding the bearing on the input

axle.

Drive axle

Dismantle the sleeve (B), the drive axle

and guide (A) to check for wear and pos-

sible replacement.

Lubricate the drive axle with grease when

assembling.

Drive axle

The drive axle can be easily pulled out of

the shaft for inspection or replacement.

The axle is guided with the help of a star

shaped, long guide (A).

Dismantle the sleeve (B) with the help of a

screwdriver or knife.

The guide (A) can now be pulled out of the

shaft for possible replacement.

Lubricate the drive axle with grease no.

503 80 17-01 when assembled in the

guide.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...