6

40

502 52 42-01

502 50 18-01

Cylinder and piston

The cylinder and the piston are two of the components exposed to most strain in the engine.

They must withstand, for example, high speeds, large temperature swings and high pressure.

Moreover, they must be resistant to wear. Despite these tough working conditions, major piston

and cylinder failure is relatively uncommon. The reasons for this include new coatings in the

cylinder bore, new types of oil and grease and refi ned manufacturing techniques.

When servicing these components, cleanliness is of the utmost importance. It is therefore

recommended that the cylinder and the area around it be thoroughly cleaned before being

dismantled from the crankcase.

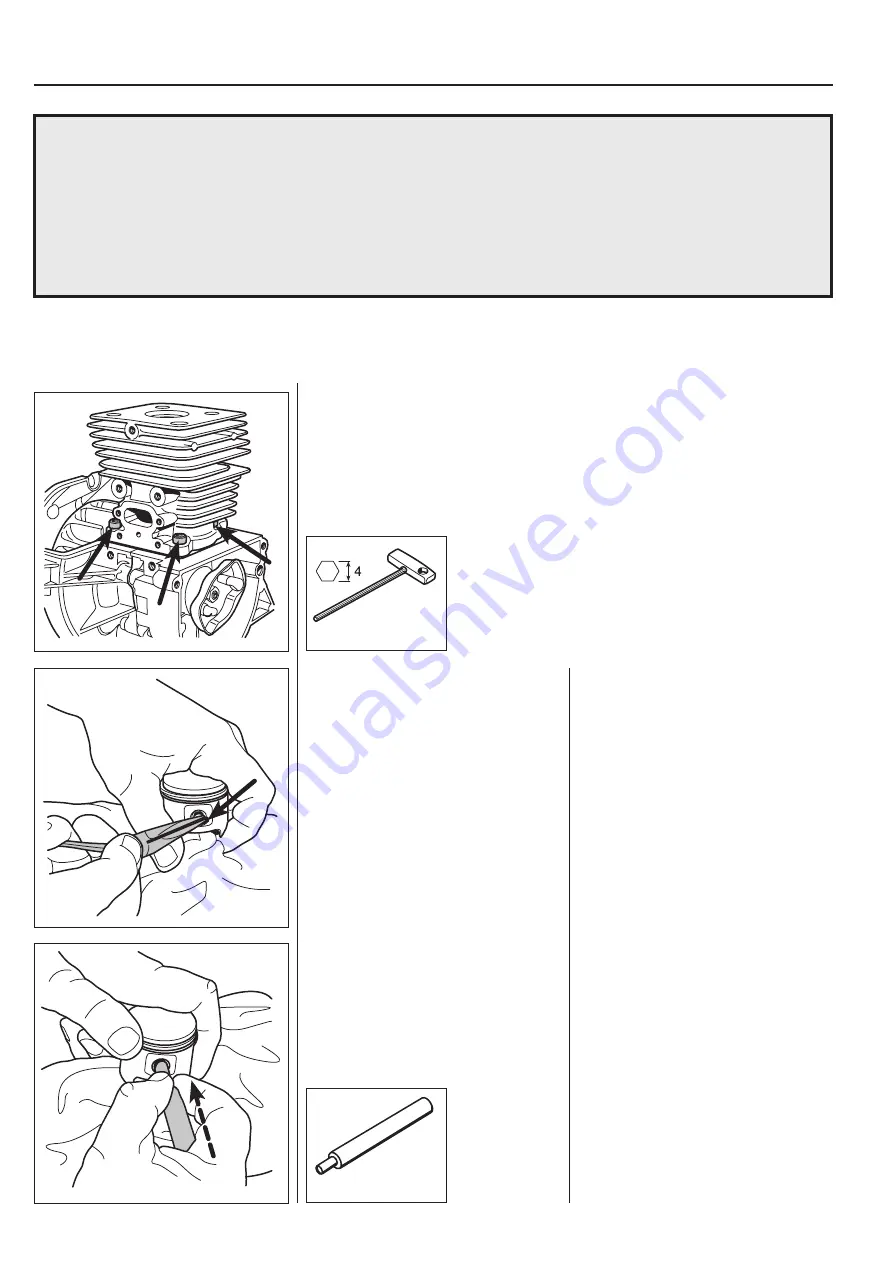

Dismantling

Dismantle the following components to make the cylinder accessible:

Starter, cylinder cover, muf

fl

er grille, muf

fl

er with heat guard plate, decompression valve

and spark plug.

Dismantle the air

fi

lter, carburettor and heat guard/distance piece (see chapter ”Fuel

system”).

Then loosen the 4 bolts holding the cylinder.

Carefully remove the cylinder straight up by rocking it

backwards and forwards. Make sure that no dirt enters the

crankcase.

Use a rag to cover the crankcase opening under the

piston.

Remove the circlips from the gudgeon pin.

Using long-nose pliers remove the

gudgeon pin circlips.

Keep your thumb over the circlip to

prevent it from

fl

ying out.

Dismantle the piston.

Push the gudgeon pin from the piston

using punch 502 52 42-01.

If the pin is too tight, carefully warm the

piston.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...