6

41

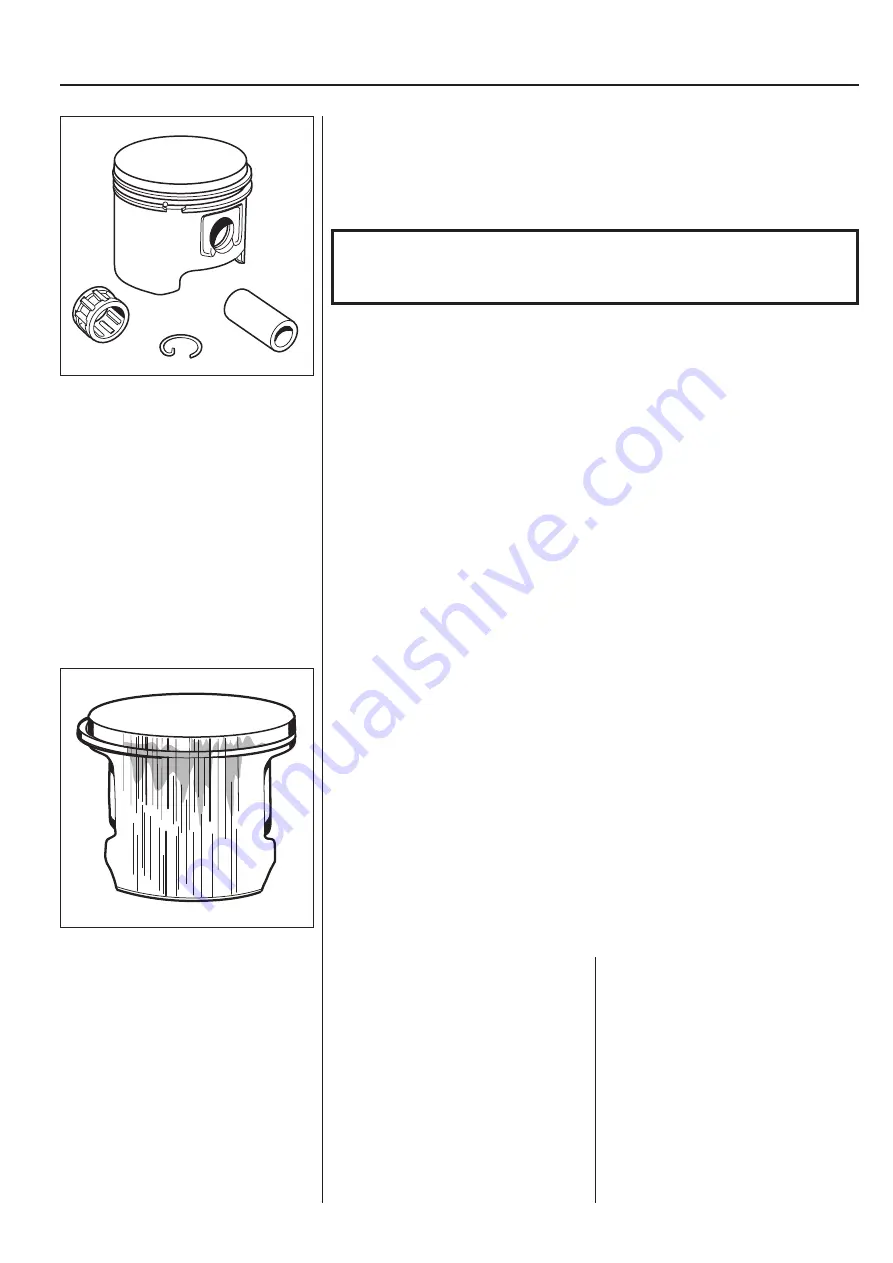

Cylinder and piston

Small to medium size scores primarily in the

middle of the exhaust port.

Cleaning, inspection

After dismantling, clean the individual components:

1. Scrape carbon deposits from the top of the piston.

2. Scrape carbon deposits from the cylinder’s combustion chamber.

3. Scrape carbon deposits from the cylinder’s exhaust port.

4. Wash all the components.

5. Inspect the different components for damage and wear.

Check the piston and cylinder for seizure damage and wear.

Also see the “Analysis and actions” section.

Check the piston ring for wear and damage.

Also see the “Analysis and actions” section.

Check the gudgeon pin.

– If it has blued, it must be replaced.

– If the piston moves too easily both the piston and the gudgeon pin must be replaced.

Check the needle bearing. If it is discoloured or damaged, it must be replaced.

Check the circlips. If they exhibit cracks or are discoloured (caused by overheating),

they must be replaced.

NOTE!

Scrape carefully with not too sharp a tool so as not to damage the

soft aluminium parts.

Cause:

• Incorrect carburettor setting.

Recommended max. speed exceeded.

• Incorrect oil mixture in the fuel.

• Too low octane fuel.

Action:

Insuffi cient lubrication

The piston has small to medium size score marks usually in front of the exhaust port. In

extreme cases heat development can be so great that material from the piston smears

along the piston skirt and even in the cylinder bore.

Generally the piston ring is undamaged and moves freely in the ring groove

There can also be scores on the inlet side of the piston.

Analysis and actions

Experience tells us that piston or cylinder failure due to manufacturing errors are

extremely rare.

The reason is usually due to other factors, which is evident from the following.

Note the reasons for the breakdown, repair the damage and take the actions required to

prevent the same thing happening again.

Change to a higher octane petrol.

Check and change the carburettor setting.

Change the fuel.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...