6

47

502 50 70-01

502 50 18-01

502 50 19-01

Cylinder and piston

NOTE!

Do not turn the cylinder, as

the piston rings can easily be

broken.

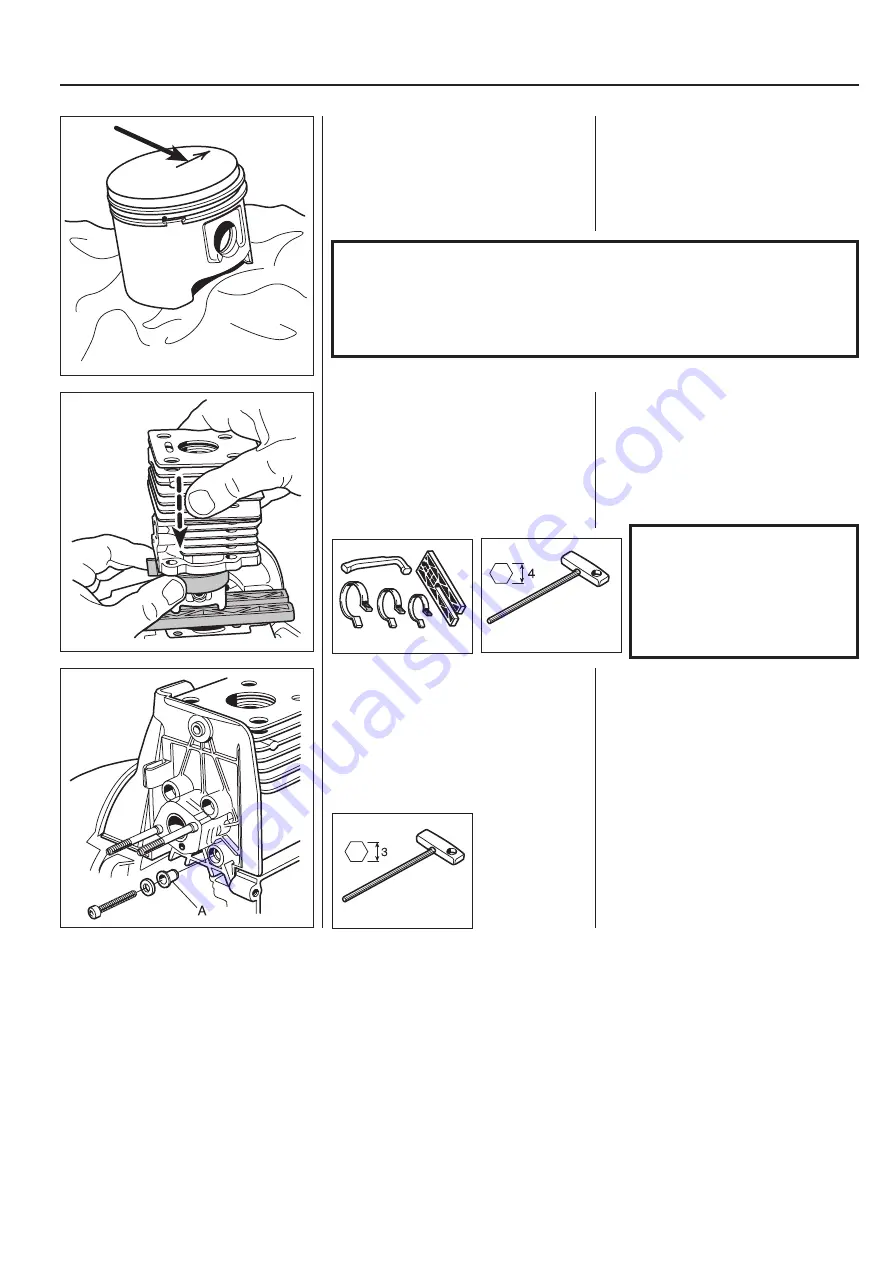

Tighten the 4 screws

diagonally crosswise.

Check that the pulse channel through the

heat guard/distance piece is completely

open. Fit the heat guard by pushing it into

place (the

fl

ange on the crankcase must

fi

t into the groove in the heat guard) and

check that the metal sleeves (A) are not

lost.

Assemble the remaining parts in the

reverse order as set out for dismantling.

See respective sections in the manual.

Fit the heat guard/distance piece.

Assembly

Lubricate the gudgeon pin’s needle

bearing with a few drops of engine oil.

Assembly

Lubricate the gudgeon pin’s needle

bearing with a few drops of engine oil.

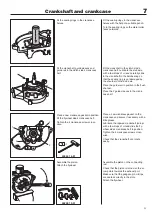

Direct the arrow on the top of the piston

towards the exhaust port. Press in the

gudgeon pin and

fi

t the circlips.

NOTE!

Place a rag in the crankcase opening to prevent the circlip from falling

into the crankcase in case it should fl y out.

Check that the circlips are correctly fi tted into the grooves by turning

the clips with fl at nosed pliers.

Check that the pulse channel in the

cylinder is open.

Assemble the cylinder with the help of

assembly set 502 50 70-01.

Check that the pulse channel in the

cylinder is open.

Place a new cylinder base gasket on

the crankcase. Lubricate the piston and

the big-end bearing with a few drops of

engine oil.

Assemble the cylinder with the help

of the piston ring compressor in the

assembly set 502 50 70-01.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...