7

54

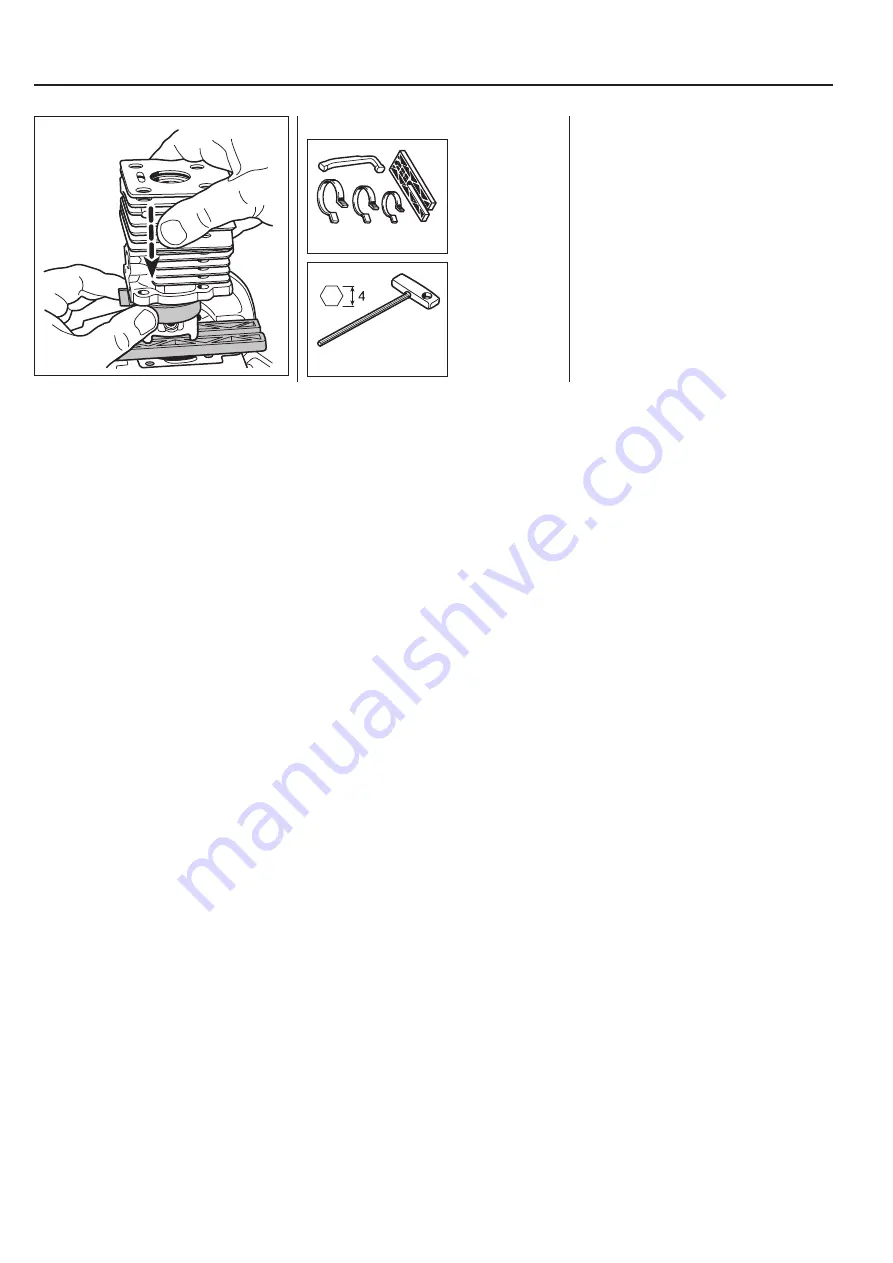

502 50 18-01

502 50 70-01

Crankshaft and crankcase

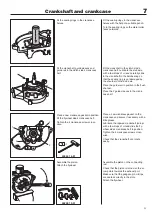

Assemble the cylinder.

Assemble the cylinder.

Position the cylinder base gasket.

Lubricate the piston and piston rings with

a few drops of oil.

Use the piston ring compressor and care-

fully slide the cylinder into position.

Tighten the four screws, crosswise.

Assemble the remaining parts in the re-

verse order as set out for dismantling.

See relevant sections in the manual.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...