GENERAL SAFETY PRECAUTIONS

188 – English

BOOTS

Wear boots with steel toe-caps and non-slip sole.

CLOTHING

Wear clothes made of a strong fabric and avoid loose

clothing that can catch on twigs and branches. Always

wear heavy, long pants. Do not wear jewellery, shorts

sandals or go barefoot. Secure hair so it is above shoulder

level.

FIRST AID KIT

Always have a first aid kit nearby.

Machine

′

s safety equipment

This section describes the machine

′

s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

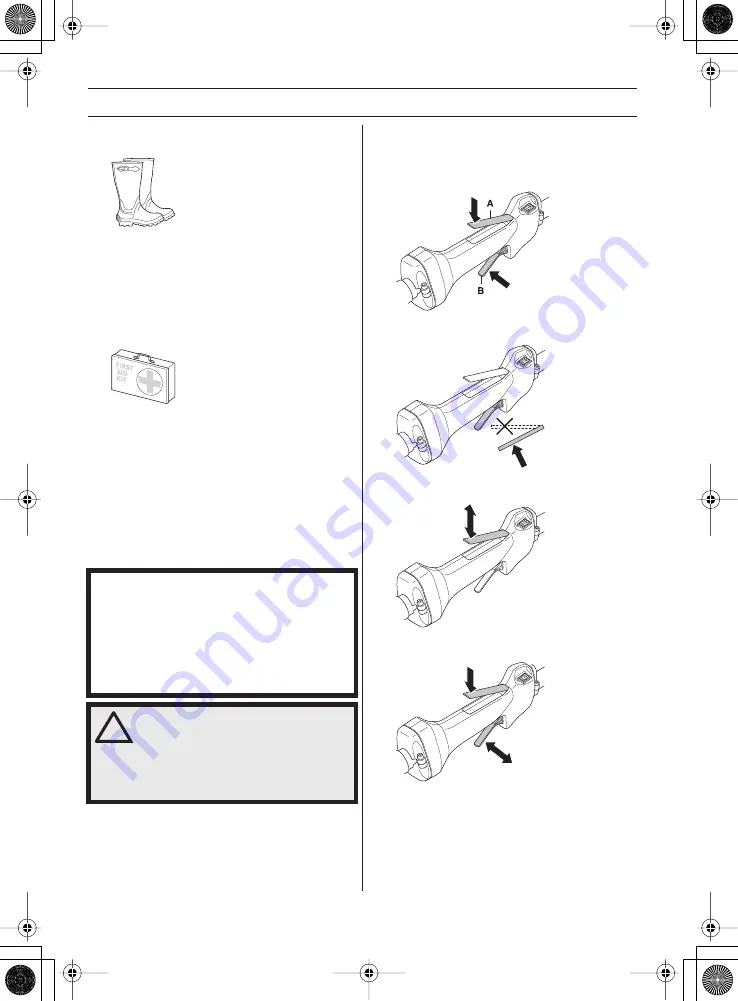

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This movement is controlled by two

independent return springs. This arrangement means that

the throttle control is automatically locked at the idle

setting.

Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

Press the throttle lockout and make sure it returns to its

original position when you release it.

Check that the throttle control and throttle lockout move

freely and that the return springs work properly.

See instructions under the heading Start. Start the

machine and apply full throttle. Release the throttle and

check that the cutting attachment stops and remains at a

standstill. If the cutting attachment rotates with the throttle

in the idle position then the carburettor idle setting must

IMPORTANT! All servicing and repair work on the

machine requires special training. This is especially true

of the machine

′

s safety equipment. If your machine fails

any of the checks described below you must contact

your service agent. When you buy any of our products

we guarantee the availability of professional repairs and

service. If the retailer who sells your machine is not a

servicing dealer, ask him for the address of your nearest

service agent.

!

WARNING! Never use a machine with

faulty safety equipment. The machine’s

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

H1151433-10,243RJ.fm Page 188 Wednesday, February 4, 2009 5:20 PM

Summary of Contents for 243RJ

Page 1: ...H1151433 10 243RJ fm Page 1 Wednesday February 4 2009 5 20 PM ...

Page 209: ...H1151433 10 243RJ fm Page 209 Wednesday February 4 2009 5 20 PM ...

Page 214: ...H1151433 10 243RJ fm Page 214 Wednesday February 4 2009 5 20 PM ...

Page 215: ...H1151433 10 243RJ fm Page 215 Wednesday February 4 2009 5 20 PM ...

Page 216: ...H1151433 10 243RJ fm Page 216 Wednesday February 4 2009 5 20 PM ...

Page 217: ...H1151433 10 243RJ fm Page 217 Wednesday February 4 2009 5 20 PM ...

Page 218: ...H1151433 10 243RJ fm Page 218 Wednesday February 4 2009 5 20 PM ...

Page 219: ...H1151433 10 243RJ fm Page 219 Wednesday February 4 2009 5 20 PM ...

Page 220: ...H1151433 10 243RJ fm Page 220 Wednesday February 4 2009 5 20 PM ...