English –

17

Correctly adjusted carburetor

A correctly adjusted carburetor means that the machine ac-

celerates without hesitation and the machine 4-cycles a little

at max speed. Furthermore, the cutting attachment must not

rotate/move at idling. A too lean adjusted low speed needle L

may cause starting dif

fi

culties and bad acceleration.

A too lean adjusted high speed needle H gives lower power =

less capacity, bad acceleration and/or damage to the engine.

A too rich adjustment of the two speed needles L and H gives

acceleration problems or too low working speed.

MAINTENANCE

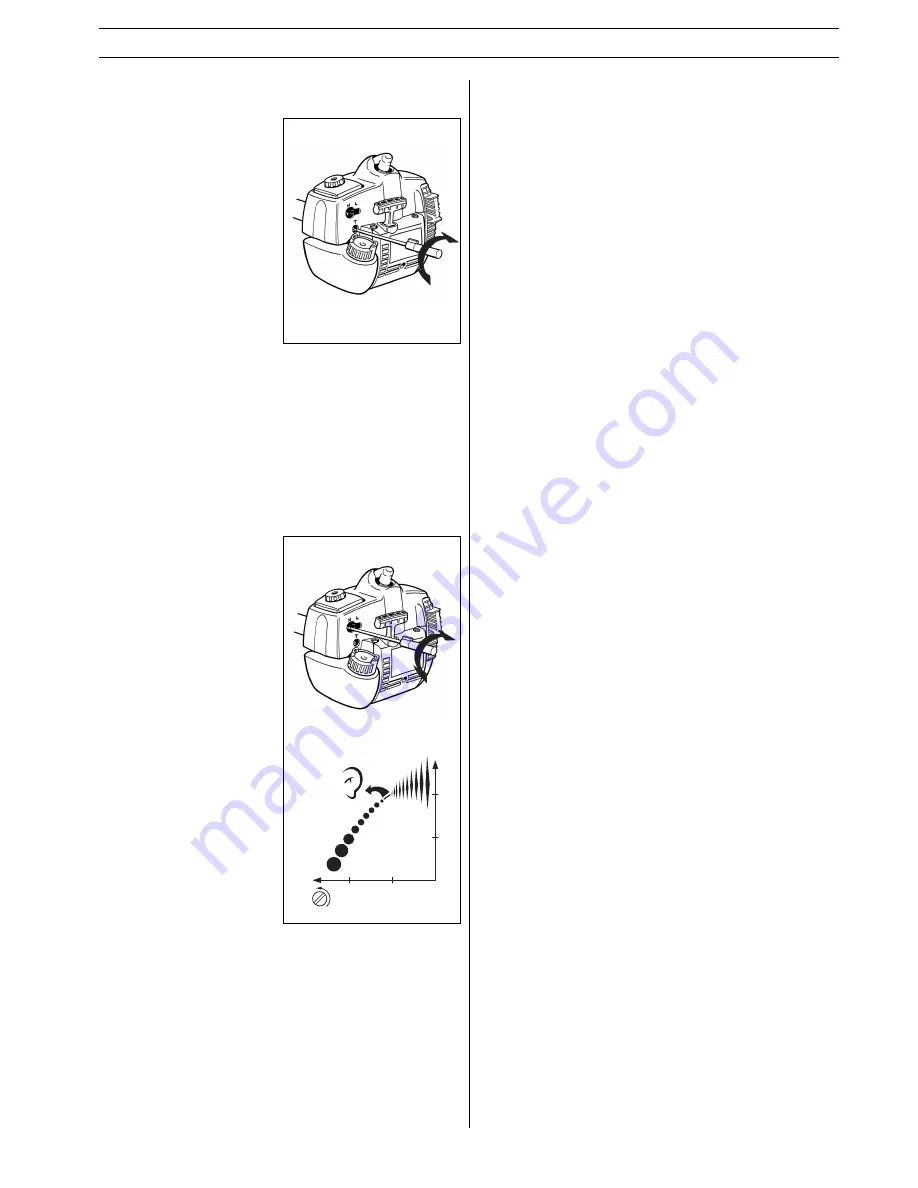

Final setting of the idling speed T

Adjust the idling speed with the

screw T, if it is necessary to re-

adjust. First turn the idle speed

adjusting screw T clockwise

until the cutting attachment

starts to rotate/move.

Then turn, counter-clockwise

until the cutting attachment

stops. A correctly adjusted idle

speed setting occurs when the

engine runs smoothly in every

position. It should also be good

margin to the rpm when the

cutting attachment starts to

rotate/move.

CAUTION! Contact your ser-

vicing dealer, if the idle speed

setting cannot be adjusted so

that the cutting attachment

stops. Do not use the machine

until it has been properly ad-

justed or repaired.

High speed needle H

The high speed needle H

in

fl

uences the power, speed,

temperature and fuel con-

sumption of the machine. A

too lean adjusted high speed

needle H (high speed needle

H closed too much) gives over-

revs and damages the engine.

Do not let the machine run at

full speed for more than 10

seconds.

Turn the high speed needle

very slowly clockwise until

engine speed is reduced.

Thereafter turn the high speed

needle very slowly counter-

clockwise and stop when the

engine begins to run roughly.

Then turn the high speed

needle slowly the minimum

amount clockwise until the

engine runs smoothly.

The high speed needle H is

correctly set when the ma-

chine ”4-cycles” a little. If the

machine ”whistles” the set-

ting is too lean. If there is too

much smoky exhaust gas at

the same time as the machine

”4-cycles” much, the setting is

too rich.

NOTE! For optimum setting of the carburetor, contact a

quali

fi

ed servicing dealer who has a revolution counter at

his disposal.

Summary of Contents for 323E, 325E

Page 23: ...English 23 NOTES ...