21

3

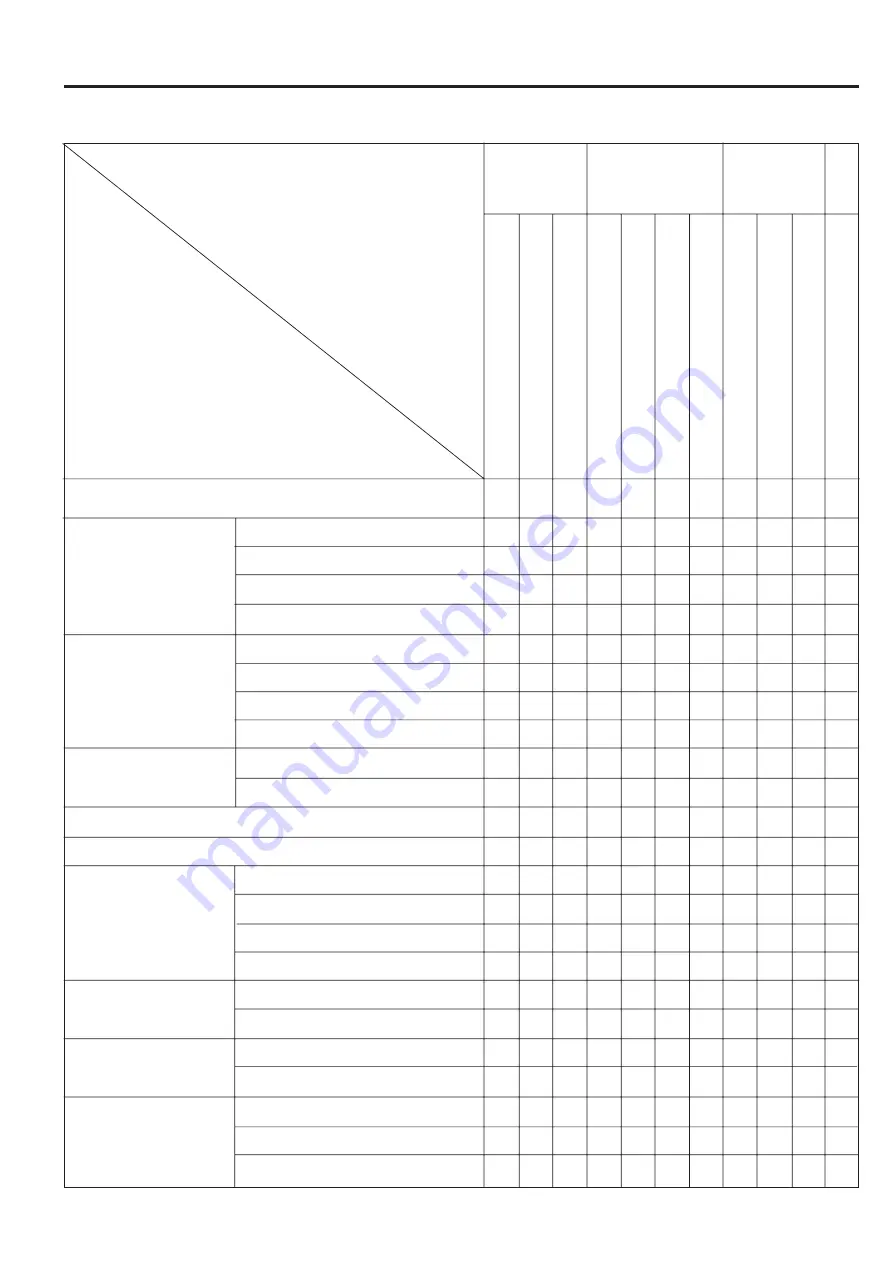

Fuel system

Symptom

Trouble Shooting Guide

Probable causes

Stop screw for the throttle not working

●

●

●

●

Fuel tank/hose

Fuel filter blocked

●

●

●

●

●

●

●

The fuel hose blocked

●

●

●

●

●

●

●

Air in fuel ducts

●

●

●

●

●

●

●

Incorrect/poor fuel

●

●

●

Pump diaphragm

Vacuum pulse leakage

●

●

Vacuum pulse duct blocked

●

●

Loose screw(s) on the pump cover

●

●

●

Faulty pump diaphragm

●

●

●

Flow bellows

Flow bellows damaged

●

The needle valve faulty

●

●

●

●

●

●

Carburettor is not fitted correctly

●

●

●

●

Faulty heat insulation seal

●

●

●

●

Needle valve’s lever

Lever arm damaged

●

●

●

●

●

Lever arm too high

●

●

●

●

Lever arm too low

●

Lever arm does not work correctly

●

●

●

●

●

●

●

●

●

●

Needle valve’s spring

The spring is deformed

●

●

●

The spring is not fitted correctly

●

●

●

●

Control diaphragm

Diaphragm is damaged

●

●

●

●

●

●

Faulty seal

●

●

●

●

Needle valve

Valve jams

●

●

●

Valve worn

●

●

●

●

●

●

●

Foreign object in the valve guide

●

●

●

●

●

●

●

Dif

ficult to start

Flooding, fuel leakage

Dif

ficult to prime when starting

Engine does not idle

Idles too slowly

Idling does not stabilise

Stops when idling

Engine does not accelerate

Engine stops when decelerating

Poor acceleration capacity

Poor performance at high speed

Starting

Low speed

Acceleration/

Deceleration

High speed

Summary of Contents for 324HDA

Page 1: ...Workshop manual 324LX 324RX 324HDA English ...

Page 25: ...24 3 Fuel system ...

Page 33: ...32 5 Angle gear ...

Page 45: ...44 7 Piston crankshaft and crankcase ...

Page 49: ...2004W26 114 02 94 26 ...