36

6

Cylinder block and valve mechanism

A

WARNING!

It is extremely important when assembling the camshaft gear

that great care is taken so that valve times are not wrong. This

can cause engine failure.

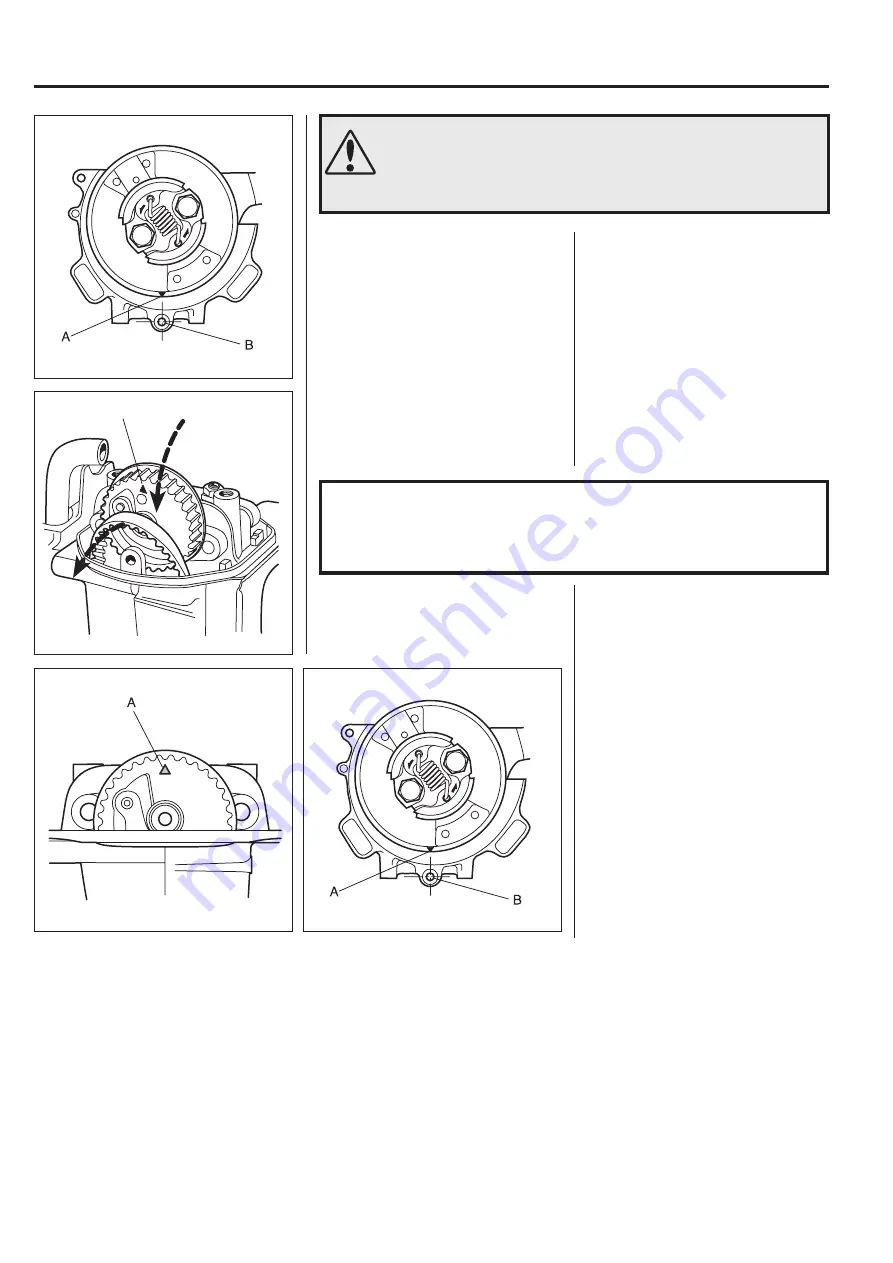

Set the marking (A) on the flywheel

directly over the centre of the hole (B).

1. Turn the flywheel until the mark (A)

centres above the hole (B) so that

the piston is positioned correctly.

Position the timing gear and position

the cam belt.

The triangular marking (A) on the gear

should point straight up.

2. Move the cam belt to one side and

insert the camshaft gear. Pay

particular attention so that the

triangular marking (A) on the gear

points straight up.

NOTE!

It is very important that the cam belt and, with that even the crankshaft,

do not rotate during this procedure. If this occurs, the valve timing will be

wrong and the risk of engine failure will be high.

Fit the axle for the camshaft gear.

3. Slide the axle for the camshaft gear

into position.

4. Check that the marking on the

flywheel and camshaft gear are

positioned correctly.

5. Check the valve clearance.

Assemble the remaining parts in the

reverse order as set out for dismantling.

Summary of Contents for 324HDA

Page 1: ...Workshop manual 324LX 324RX 324HDA English ...

Page 25: ...24 3 Fuel system ...

Page 33: ...32 5 Angle gear ...

Page 45: ...44 7 Piston crankshaft and crankcase ...

Page 49: ...2004W26 114 02 94 26 ...