38

6

Cylinder block and valve mechanism

2

1

Dismantle the crankshaft and the cam

belt.

Pull away the sealing rings from the

crankshaft .

Lift up the crankcase and pull the piston

out of the cylinder bore.

NOTE!

Note the cam belt’s direction of

rotation (for example, from which

direction the text on the belt can

be read) so it rotates in the same

direction when reassembled.

Pull away the sealing rings from the

crankshaft .

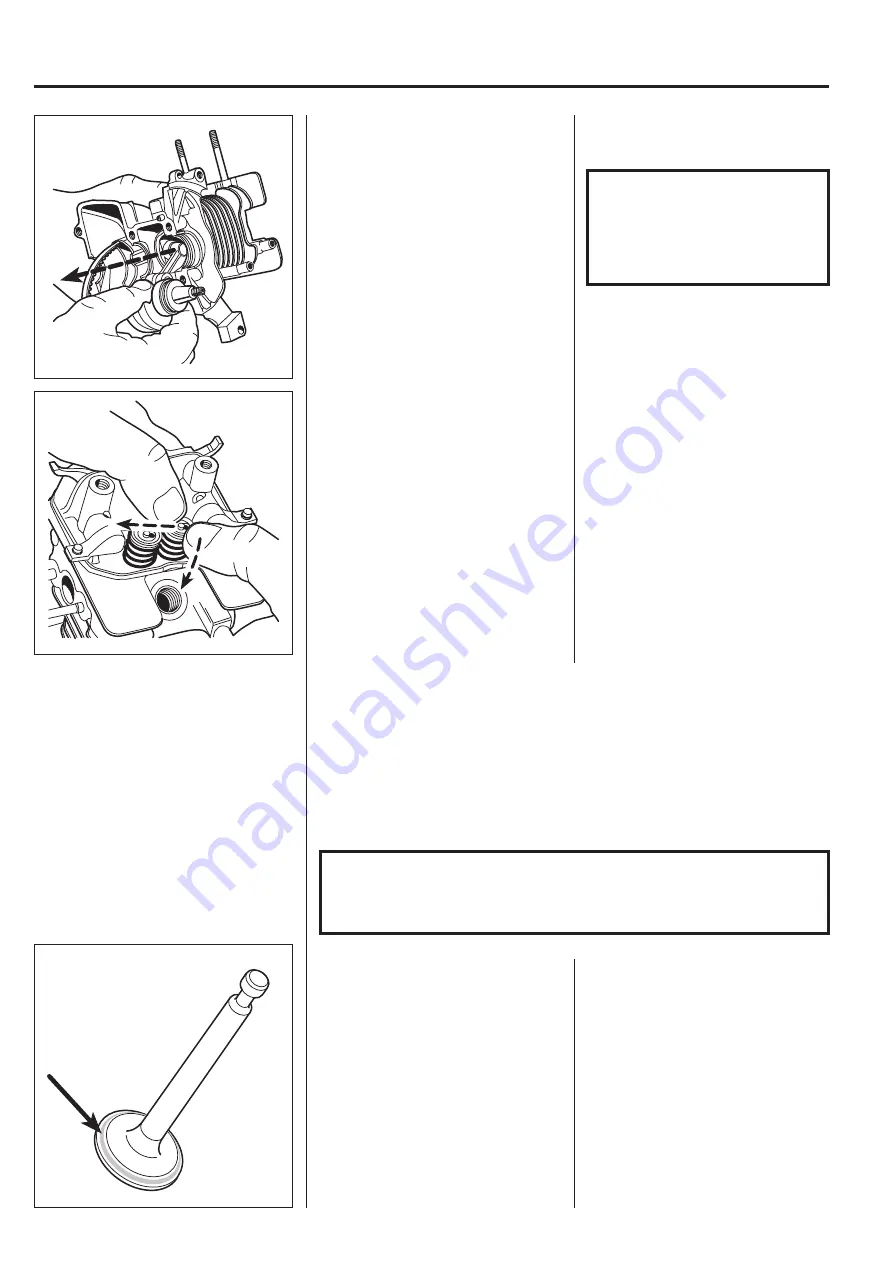

Dismantle the valves.

Press together the spring with your

thumbs and remove the valve disc.

Lift out the valve spring and the valve.

Check the component parts with regard

to damage and wear.

Dismantle the valves.

Insert a rolled-up cloth in the cylinder

bore to support the valves when

dismantling the valve discs.

Press down valve disc with your

thumbs and move it to the adjacent cut-

out.

Lift out the disc, valve spring and valve.

Standard dimensions, wear tolerances

Component

Standard

Wear limit

Valve spring length

20.66 mm

20.00 mm

Valve spindle diameter, exhaust

3.435 – 3.450 mm

3.380 mm

Valve spindle diameter, inlet

3.470 – 3.485 mm

3.400 mm

Valve guide inner diameter

3.500 – 3.518 mm

3.560 mm

Clearance, valve spindle/valve guide, exhaust

0.050 – 0.083 mm

0.120 mm

Clearance, valve spindle/valve guide, inlet

0.015 – 0.048 mm

0.098 mm

Timing gear inner diameter

4.020 – 4.050 mm

4.100 mm

Cam height

22.097 mm

21.797 mm

NOTE!

When the valve guides are worn in excess of the wear tolerances these

cannot be changed separately but the entire cylinder block must be

replaced with a new one.

Clean the valves and grind them in

using valve grinding compound.

Clean the valves thoroughly before

assembling.

The valves are marked:

HI = inlet valve

HE = exhaust valve

Clean off any deposits from the valves

(especially the exhaust valve) using a

wire brush.

Check the valve head for signs of

cracking.

Small unevenness can be ground away

using valve grinding compound.

Apply a thin layer of bearing paste on

the valve head. Insert the valve in the

guide and rotate it back and forth.

Repeat the procedure until a matt, grey,

unbroken stripe (approximately 0.8 mm

wide) is visible around the head and

valve seating.

Clean the valves thoroughly before

assembling.

Summary of Contents for 324HDA

Page 1: ...Workshop manual 324LX 324RX 324HDA English ...

Page 25: ...24 3 Fuel system ...

Page 33: ...32 5 Angle gear ...

Page 45: ...44 7 Piston crankshaft and crankcase ...

Page 49: ...2004W26 114 02 94 26 ...