14

– English

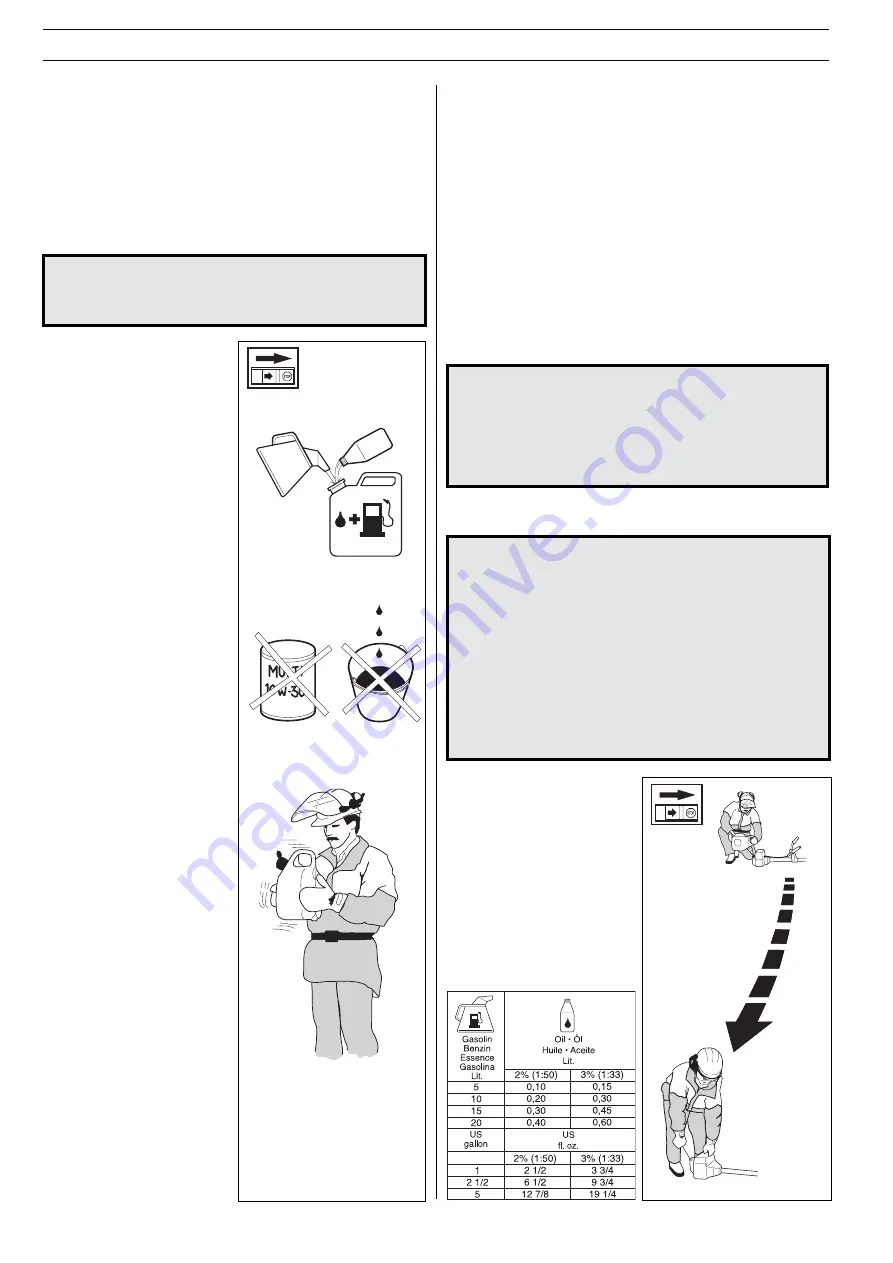

Fuel mixture

NOTE!

The edger is

fi

tted with two-stroke engines and must always

be run on a mixture of petrol and two-stroke oil. To ensure

the correct mixture proportions it is important to measure the

quantity of oil accurately. When mixing small amounts of fuel

small discrepancies in the amount of oil have a great bearing on

the proportions of the fuel mixture.

FUEL HANDLING

Petrol

• Always use unleaded, oil

mixed, quality petrol! (at least

90 octane). Leaded petrol

will destroy the catalytic

converter and it will no longer

serve its purpose.

• The lowest recommended

octane rating is 90. If you

run the engine on a petrol

with a lower octane rating

than 90 so-called “knocking”

can occur. This leads

to an increased engine

temperature, which can

result in a serious engine

breakdown.

• When working at continuous

high revs a higher octane

rating is recommended.

Two-stroke oil

• For the best results use

HUSQVARNA two stroke oil,

which has been specially

developed for 2-stroke

engines. Mixing ratio 1:50

(2%).

• If HUSQVARNA two stroke

oil is not available you can

use a high quality two-stroke

oil intended for air cooled

engines. Contact your dealer

when selecting an oil. Mixing

ratio: 1:33 (3%).

• Never use two-stroke oil

intended for water cooled

outboard motors, so-called

outboard motor oil.

• Never use oil intended for

four-stroke engines.

Mixture

• Always mix petrol and oil in a clean container intended for

petrol.

• Always start by

fi

lling half the quantity of petrol required. Then

add the entire oil quantity. Mix (shake) the fuel mixture. Fill the

remaining quantity of petrol.

• Mix (shake) the fuel mixture carefully before

fi

lling in the

machine

ʼ

s fuel tank.

• Do not mix fuel for more than max. one month's supply of fuel.

• If the edger is not used for a long period of time, the fuel tank

should be emptied and cleaned.

Fuelling

!

WARNING!

The following precautions reduce the risk of

fi

re:

Do not smoke or place any sources of heat in

the vicinity of the fuel.

Never refuel when the engine is running.

Always stop the engine and let it cool for a

few minutes before refuelling.

Open the fuel cap slowly when fuelling so that

any over pressure is released slowly.

Tighten the fuel cap carefully after refuelling.

Always move the machine from the fuelling

area before starting.

• Clean around the fuel cap.

Contamination in the tank can

disrupt operations.

• Ensure that the fuel is

well mixed by shaking the

container before

fi

lling the

tank.

!

WARNING!

The catalytic converter muf

fl

er becomes very

hot during and after use. This also applies

during idling. Be aware of the

fi

re hazard,

especially when handling the saw near

fl

ammable substances or vapours.

WARNING!

Always provide good ventilation when

handling fuel.

!