English –

7

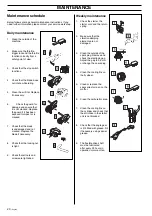

6. Cutting equipment

SAFETY INSTRUCTIONS

The two basic rules:

1. Only use the cutting equip-

ment we recommend! See

chapter

“Technical data”

.

2. Check the cutting equip-

ment with regard to dam-

age and crack formation.

Damaged cutting equip-

ment should always be

replaced.

!

7. Locking nut

• Protect your hand from injury

when assembling, use the

blade guard as protection

when tightening with a socket

spanner. Tighten the nut by

turning against the direction

of rotation. Loosen the nut

by turning in the direction of

rotation. (NOTE! the nut has

a left-hand thread).

• Tighten the nut using a

socket spanner, 35 - 50 Nm

(3.5 - 5 kpm).

WARNING!

Always stop the engine before starting work

on any part of the cutting equipment. This

continues to rotate even after the throttle has

been released. Ensure that the cutting equip-

ment has stopped completely and remove the

cable from the spark plug before you start to

work on it.

WARNING!

Never use a machine with defective safety

equipment. The safety equipment should

be maintained as described in this section.

If your machine does not meet any of these

controls you should contact your service

workshop.

!

NOTE!

The locking nut

ʼ

s nylon lock must not be so worn that it can be

turned by hand. The lock shall hold at least 1.5 Nm. The nut

should be replaced after it has been put on approx. 10 times.