8

– English

General safety instructions

SAFETY INSTRUCTIONS

IMPORTANT INFORMATION

• The machine is only designed for cutting the edges of

lawns.

• The only accessories to be used with the engine unit

as a drive source are the cutting units we recommend

in the chapter

“Technical data”.

• The operator is responsible for accidents and the risk

people and property are exposed to.

• Never use the machine if you are tired, if you have

consumed alcohol, or if you are taking medicines that

can affect your sight, your judgement or the control of

your body.

• Do not operate when it's dark.

• Use personal protective equipment. See the section

“Personal protective equipment”.

• Never use a machine that has been modi

fi

ed so that it

no longer corresponds with the original design.

• Never use a machine that is faulty. Follow the mainte-

nance, control and service instructions in this Opera-

tor

ʼ

s Manual. Some maintenance and service actions

should be carried out by trained and quali

fi

ed special-

ists. See the chapter

“Maintenance”.

• All covers and guards must be

fi

tted before starting

the machine. Check that the spark plug cap and HT

lead are not damaged, otherwise you could get an elec-

tric shock.

Safety instructions before starting work

• Inspect the working area. Remove any objects, such as

stones, broken glass, nails, steel wire, string, etc. that can be

thrown or can wrap around the blade or blade guard.

• Keep others at a safe distance. Children, animals, onlookers

and helpers should stand outside of the safety zone of 15 m

(50 feet). Stop the machine immediately if any one should ap-

proach.

• Check the entire machine before starting work. Replace dam-

aged parts. Check for fuel leakage and that all safety guards

and covers are complete and fastened securely. Check all

nuts and bolts

• Check the blade for cracks or

any other damage.

• Ensure the blade guard is

mounted and not damaged.

• Check that the blade and blade guard are correctly secured.

• When adjusting the carburettor make sure the blade is held

against the ground and that no one is in the immediate vicinity.

• Make sure the blade does not rotate when idling.

• Make sure the handle and safety features are in order. Never

use a machine that has parts missing or has been changed in

relation to the speci

fi

cation.

• Only use the machine for the purpose it was intended for.

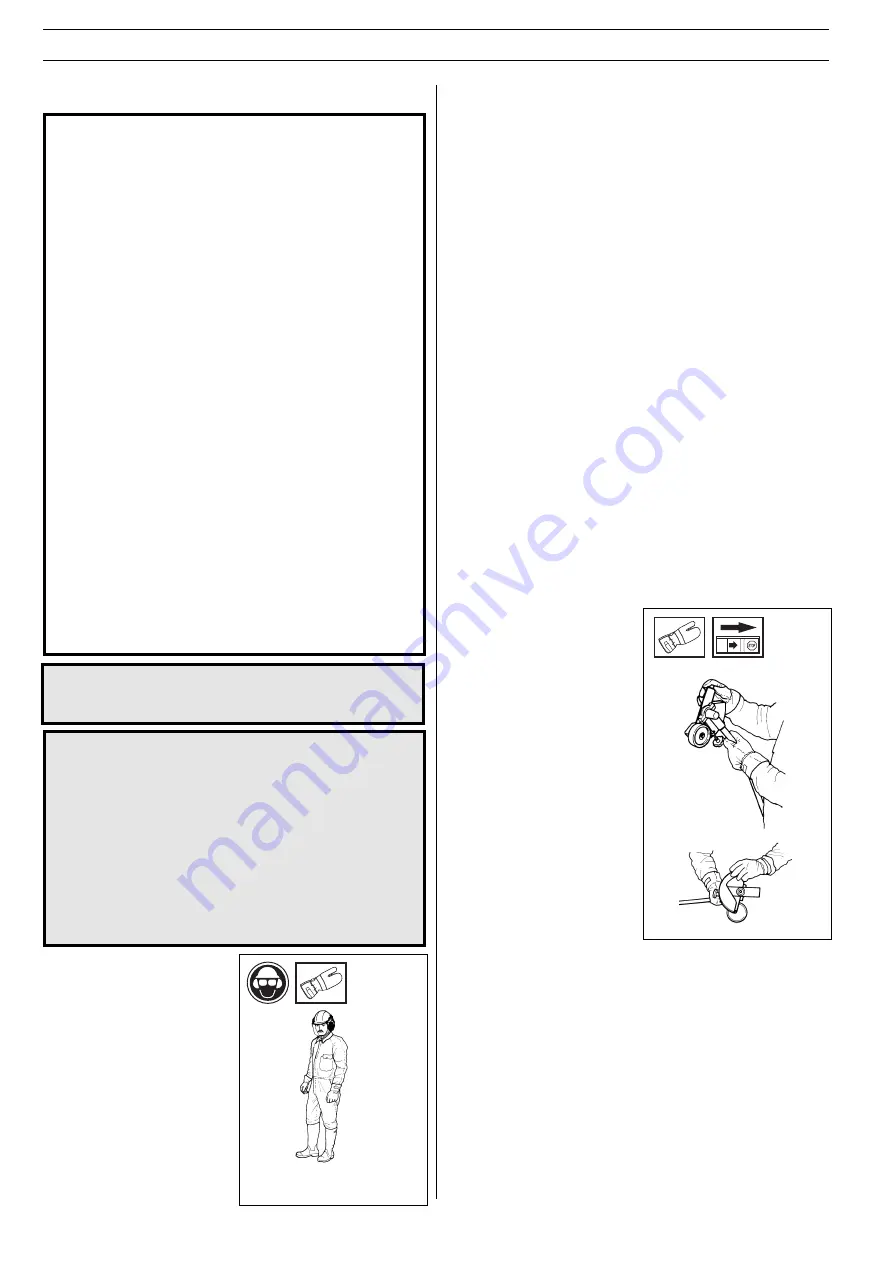

Personal protection

• Always wear boots and other

equipment described in the

section

“Personal protective

equipment”

.

• Always wear working clothes

and heavy-duty long trousers.

• Never wear loose sitting

clothes or jewellery.

• Persons with long hair

should, for personal safety,

put their hair up.

Safety instructions regarding the surround-

ings

• Never allow children to use the machine.

• Ensure no one comes closer than 15 metres when working.

• Never allow anyone else to use the machine without

fi

rst en-

suring that they have understood the contents of the Opera-

tor

ʼ

s Manual.

WARNING!

Faulty cutting equipment increases the risk

of accidents.

!

WARNING! Never allow children to use or

be in the vicinity of the machine. As the

machine is equipped with a spring-loaded

stop switch and can be started by low

speed and force on the starter handle,

even small children under some circum-

stances can produce the force necessary

to start the machine. This can mean a

risk of serious personal injury. Therefore

remove the spark plug cap when the ma-

chine is not under close supervision.

!