English –

9

7. Quick-release

• Check that the harness

straps are correctly

positioned. When the

harness and machine are

adjusted, check the harness‘

safety release catch to

ensure it works correctly.

SAFETY INSTRUCTIONS

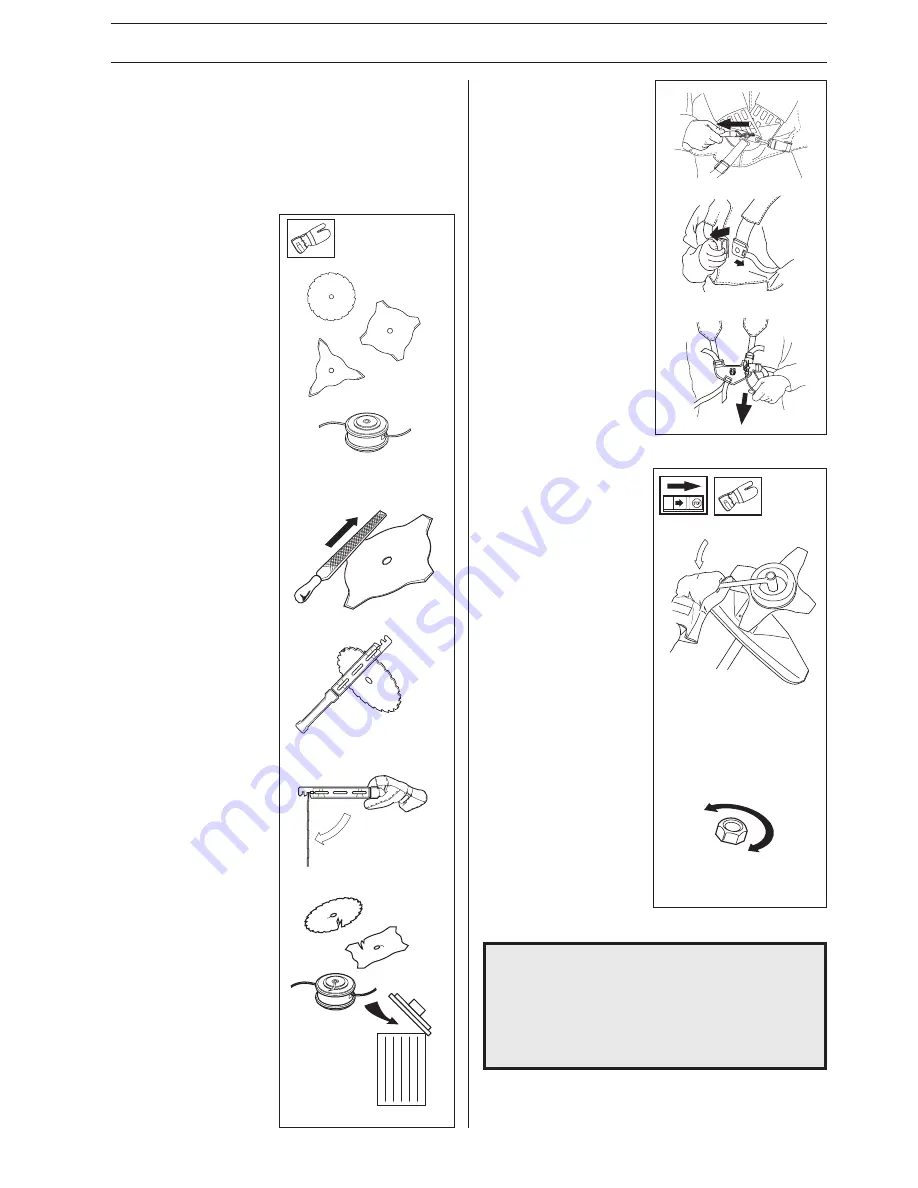

6. Cutting equipment

This section describes how through correct maintenance and

through using the right type of cutting equipment you can:

• Reduce the machine‘s tendency to kickback

• Obtain maximum cutting capacity.

• Increase the service life of the cutting equipment.

Four basic rules:

1)Only use the cutting

and guard equipment

we recommend! See

chapter “Technical

data“.

2)Keep the blade‘s teeth

well and correctly

sharpened! Follow our

instructions and use the

recommended filing

gauge. An incorrectly

sharpened or damaged

blade increases the risk

of an accident.

3)Keep the correct setting.

Follow our instructions

and use the

recommended setting

tool. An incorrectly set

blade increases the risk

of jamming and

kickback.

4)Check the cutting

equipment with regard

to damage and crack

formation. Damaged

cutting equipment

should always be

replaced.

!

WARNING!

Never use a machine with defective

safety equipment. The safety equipment

should be maintained as described in this

section. If your machine does not meet

any of these controls you should contact

your service workshop.

8. Locking nut

• Protect your hand from

injury when assembling,

use the blade guard as

protection when tightening

with a socket spanner.

Tighten the nut by turning

against the direction of

rotation. Loosen the nut by

turning in the direction of

rotation. (NOTE! the nut

has a left-hand thread).

• Tighten the nut using a

socket spanner, 35 - 50

Nm (3.5 - 5 kpm).

NOTE!

The locking nut‘s nylon lock

must not be so worn that it

can be turned by hand. The

lock shall hold at least 1.5

Nm. The nut should be

replaced after it has been put

on approx. 10 times.