20 –

English

MAINTENANCE

Carburetor

Your Husqvarna product has been designed and

manufactured to speci

fi

cations that reduce harmful

emissions. After the engine has used 8-10 tanks of fuel the

engine will be run-in. To ensure that it continues to run at peak

performance and to minimise harmful exhaust emissions

after the running-in period, ask your dealer/service workshop

(who will have a rev counter at their disposal) to adjust your

carburettor.

Function

•

The carburetor governs the engine’s speed via the throttle

control. Air and fuel are mixed in the carburetor. The air/

fuel mixture is adjustable. Correct adjustment is essential

to get the best performance from the machine.

•

The setting of the carburetor means that the engine is

adapted to local conditions, for example, the climate,

altitude, fuel and the type of 2-stroke oil.

•

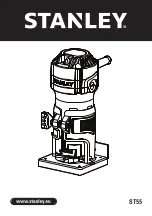

The carburetor has three adjustment controls:

L = Low speed jet

H = High speed jet

T = Idle adjustment screw

•

The L and H-jets are used to adjust the supply of fuel to

match the rate that air is admitted, which is controlled with

the throttle. If they are screwed clockwise the air/fuel ratio

becomes leaner (less fuel) and if they are turned anti-

clockwise the ratio becomes richer (more fuel). A lean

mixture gives a higher engine speed and a rich mixture

gives a lower engine speed.

•

The T-screw regulates the throttle setting at idle speed. If

the T-screw is turned clockwise this gives a higher idle

speed; turning it anti-clockwise gives a lower idle speed.

Basic setting

•

The basic carburetor settings are adjusted during testing

at the factory. The basic setting is richer than the optimal

setting and should be maintained for the

fi

rst few hours the

machine is in use. The carburettor should then be

fi

nely

adjusted. Fine adjustment should be carried out by a

skilled technician.

CAUTION!

If the cutting attachment rotates when the engine

is idling the idle adjustment screw T should be turned anti-

clockwise until the cutting attachment stops.

Rec. idle speed

2700 rpm

Recommended max. speed:

See the Technical data section.

Fine adjustment

•

When the machine has been ”run-in” the carburetor

should be

fi

nely adjusted.

The

fi

ne adjustment should

be carried out by a quali

fi

ed person.

First adjust the L-

jet, then the idling screw T and then the H-jet.

Conditions

•

Before any adjustments are made, make sure that the air

fi

lter is clean and the air

fi

lter cover is

fi

tted. If you adjust

the carburettor when the air

fi

lter is dirty it will result in a

leaner mixture when the

fi

lter is

fi

nally cleaned. This can

lead to serious engine damage.

•

Carefully turn both jets, L and H, so that they are midway

between fully screwed in and fully screwed out.

•

Do not attempt to adjust the L and H jets beyond either

stop as this could cause damage.

•

Now start the machine according to the starting

instructions and let it warm up for 10 minutes.

CAUTION!

If the cutting attachment rotates when the engine

is idling the idle adjustment screw T should be turned anti-

clockwise until the cutting attachment stops.

Low speed jet L

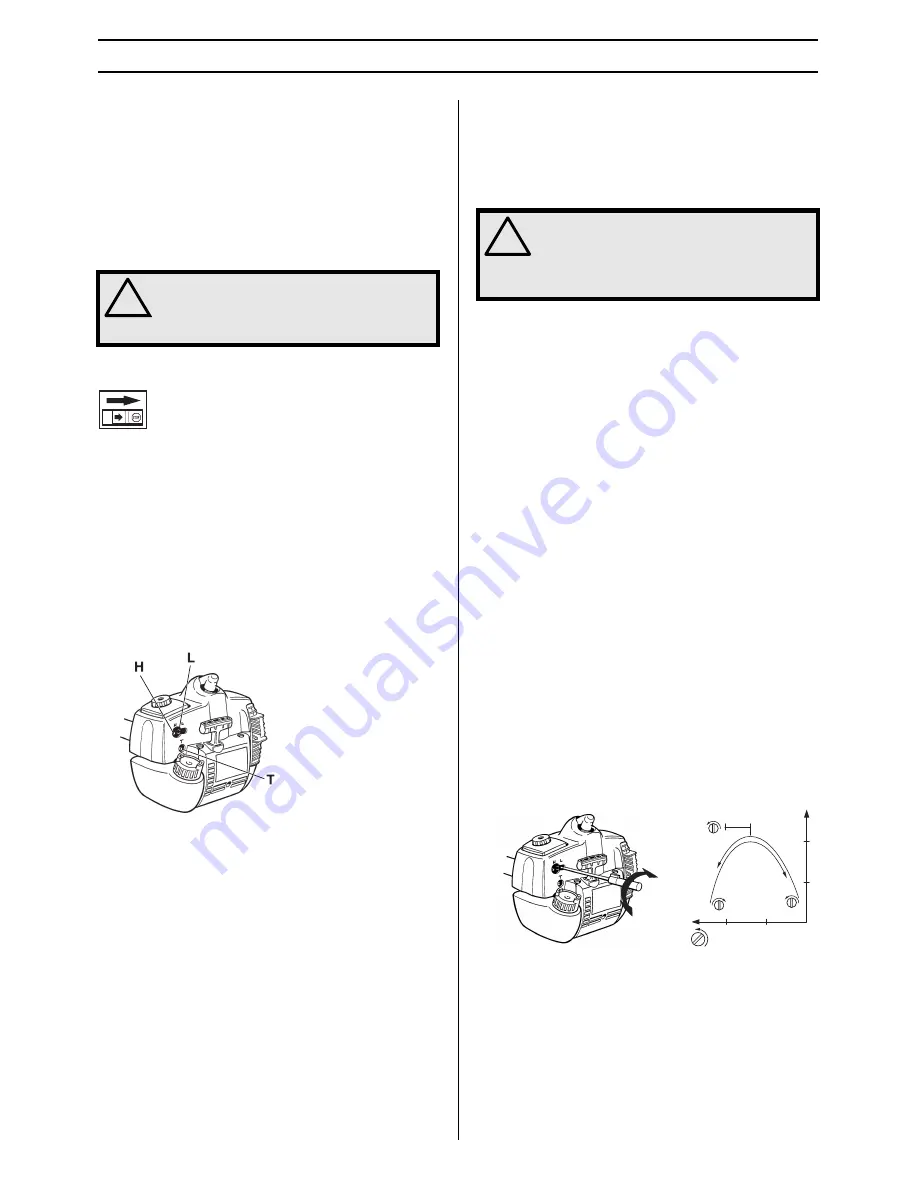

Try to

fi

nd the highest idling speed, turning the low speed

needle L clockwise respectively counter-clockwise. When the

highest speed has been found, turn the low speed needle L 1/

4 turn counter-clockwise.

CAUTION!

If the cutting attachment rotates when the engine

is idling the idle adjustment screw T should be turned anti-

clockwise until the cutting attachment stops.

Fine adjustment of the idle speed T

Adjust the idle speed using the idle adjustment screw T, if it is

necessary to readjust. First turn the idle adjustment screw T

clockwise until the cutting attachment starts to rotate. Then

turn the screw anticlockwise until the cutting attachment

stops. The idle speed is correctly adjusted when the engine

!

WARNING! The complete clutch cover and

shaft must be

fi

tted before the machine is

started, otherwise the clutch can come loose

and cause personal injury.

!

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until it

has been correctly adjusted or repaired.

L

+ 1/4

Summary of Contents for 326RJX Series

Page 28: ......

Page 29: ...1 Trimmy H II 2 3 4 5 6 7 8 9 7 5 m 25 2 0 2 4 mm 080 095 1 2 15 cm 6 3 7 m 12 15 cm 6 ...

Page 32: ... Clic 1 2 3 5 6 7 10 11 8 5 m 28 4 8 4 2 m 14 2 4 2 7 mm 095 106 10 cm 4 6 15 cm S35 ...

Page 33: ...1 2 4 3 2 4 2 7 mm 095 106 4 25 m 14 4 25 m 14 B 6 15 cm A 6 15 cm S35 5 ...

Page 35: ......