MAINTENANCE

20 – English

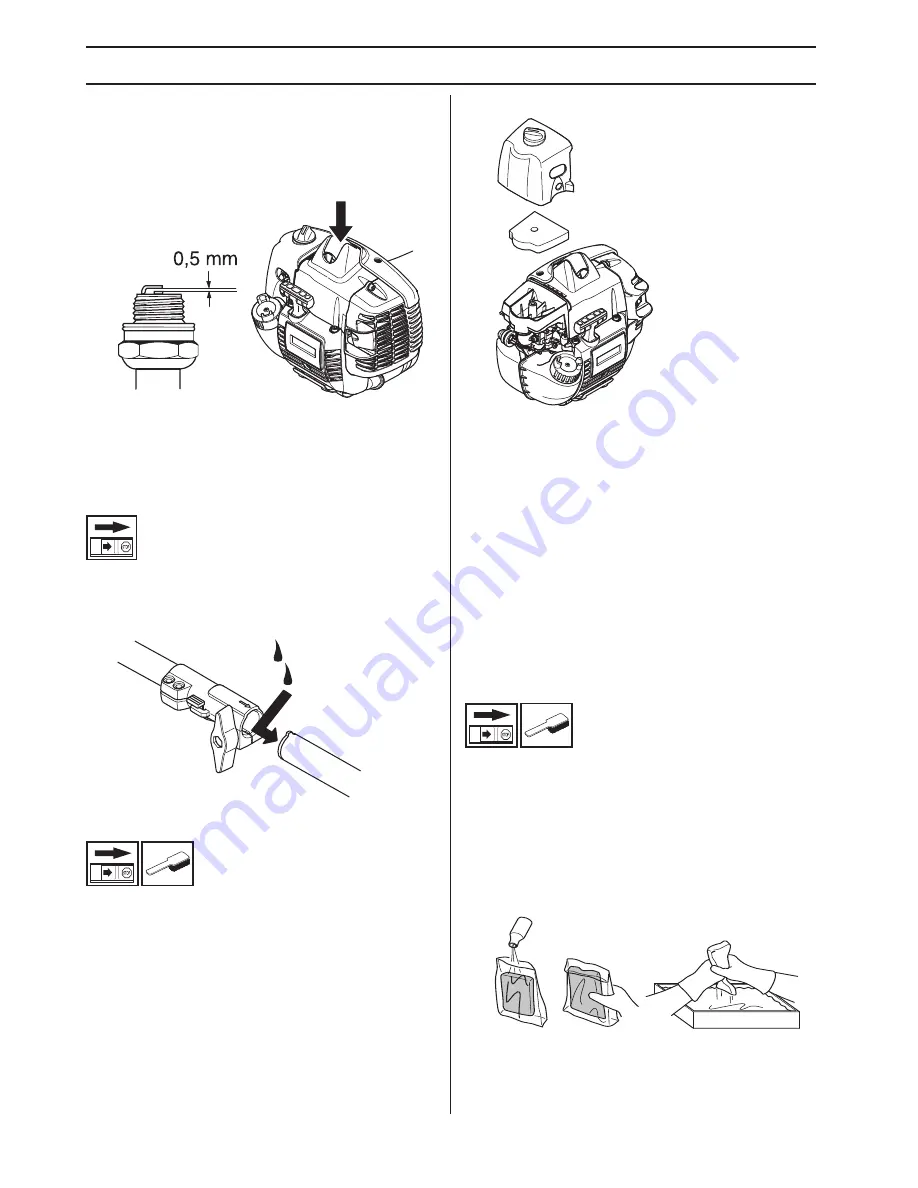

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0.5 mm. The

spark plug should be replaced after about a month in

operation or earlier if necessary.

CAUTION!

Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor.

Two-piece shaft (327LDx)

The drive shaft end in the lower shaft should be lubricated

with grease every 30 hours. There is a risk that the drive

shaft ends (splined coupling) on models with two-piece

shafts will seize if they are not lubricated regularly.

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

•

Carburettor malfunctions

•

Starting problems

•

Loss of engine power

•

Unnecessary wear to engine parts.

•

Excessive fuel consumption.

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

A damaged air filter

must always be replaced.

If the machine is used in dusty conditions the air filter

should be soaked in oil. See instructions under the

heading Oiling the air filter.

Oiling the air filter

Always use HUSQVARNA filter oil, art. no. 531 00 92-48.

The filter oil contains a solvent to make it spread evenly

through the filter. You should therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour

off the excess before fitting the filter to the machine. Never

use common engine oil. This would drain through the filter

quite quickly and collect in the bottom.

Summary of Contents for 327LS

Page 25: ......

Page 26: ... Clic 1 2 3 5 6 7 10 11 8 5 m 28 4 8 4 2 m 14 2 4 2 7 mm 095 106 10 cm 4 6 15 cm S35 ...

Page 27: ...1 2 4 3 2 4 2 7 mm 095 106 4 25 m 14 4 25 m 14 B 6 15 cm A 6 15 cm S35 5 ...

Page 28: ...T35 T35x Clic 1 2 3 5 6 7 9 8 5 m 28 4 8 4 3 m 14 2 4 2 7 mm 095 106 10 cm 4 6 15 cm ...

Page 29: ... Clic 1 2 3 5 6 7 9 6 0 m 18 4 8 3 05 m 9 2 0 2 4 mm 079 095 10 cm 4 6 15 cm T25 ...

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ...Original instructions z Wb 6q z Wb 6q 2013 09 26 1155663 26 ...