Summary of Contents for 333R

Page 1: ...Workshop manual 333R 335R English ...

Page 2: ......

Page 36: ...34 4 Centrifugal clutch ...

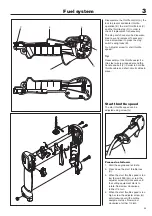

Page 40: ...38 5 Angle gear ...

Page 50: ...48 6 Cylinder and piston ...

Page 60: ......

Page 61: ......

Page 62: ...2005W23 115 00 92 26 ...