36

5

Angle gear

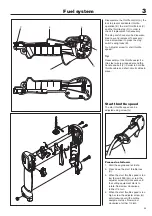

Dismantling

1.Remove the cutting equipment and

guard.

2.Remove the screws (A) and lift off

the plate (B).

3.Loosen the screw (C) holding the

angle gear on the shaft and remove

the angle gear.

The angle gear has two purposes:

The first is to gear down the engine’s high speed to better suit the lower speed a saw blade or trimmer

requires to work efficiently.

Secondly, the angle gear contributes towards the operator’s working stance so that it is comfortable and

at the same time efficient. In other words, the power from the engine via the drive axle should be angled

so that the cutting tool works parallel with the ground.

4.Remove the circlip (D).

5.Remove the large circlip holding the

ball-bearing on the input shaft.

Dismantling

Remove the angle gear from the shaft.

Remove the circlips holding the

bearings on the input respective output

shafts.

Heat the entire angle gear to approx.

110°C and first dismantle the input axle

and then the output axle.

Heat the entire angle gear using a hot

air gun to approx. 110°C.

Knock the gear against a wooden block

so that the input axle and the bearing

fall out.

Now lift out the output axle.

Wear protective gloves.

Summary of Contents for 333R

Page 1: ...Workshop manual 333R 335R English ...

Page 2: ......

Page 36: ...34 4 Centrifugal clutch ...

Page 40: ...38 5 Angle gear ...

Page 50: ...48 6 Cylinder and piston ...

Page 60: ......

Page 61: ......

Page 62: ...2005W23 115 00 92 26 ...