50

7

Crankshaft and crankcase

502 50 18-01

The task of the crankshaft is to transform the reciprocating motion of the piston to rotation. This requires a

stable design withstanding immense pressure and rotational and bending strain, as well as high rotational

speed. In addition the connecting rod is exposed to large acceleration and retardation forces as it moves

between the top and bottom dead centres. This puts special demands on the bearings that must withstand

quick changes in load. Moreover, the bearing’s roller retainer must also cope with high temperatures and

friction. It is therefore extremely important when servicing to check the roller retainer for cracks, wear and

discolouration caused by overheating.

The crankshaft is journalled in the crankcase on heavy-duty ball bearings. In addition to the journalling

point for the crankshaft, the crankcase acts as a scavenging pump for the fuel/air mixture when this is

“sucked” from the carburettor and is forced into the cylinder’s combustion chamber. The crankcase must

be perfectly sealed so as not to affect this pump function. There cannot be any leakage from the crank-

shaft, between the crankcase halves or between the crankcase and the cylinder.

Always replace the sealing rings and gaskets when servicing the crankcase.

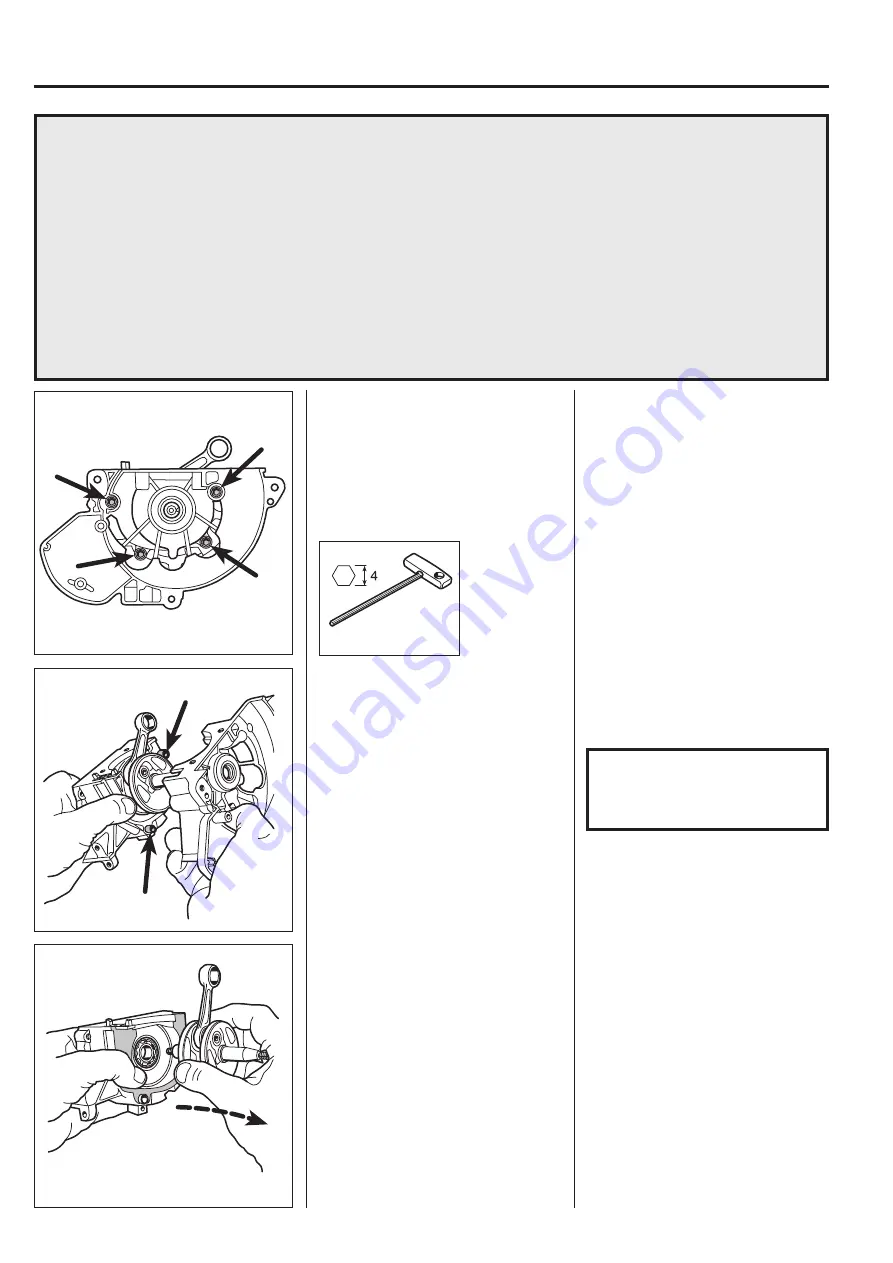

Dismantling

Dismantle all components so that only

the crankcase and crankshaft remain.

Dismantling

Dismantle all components so that only

the crankcase and crankshaft remain.

See the respective sections for detailed

information if necessary.

Dismantle the 4 screws holding the

crankcase halves together.

Separate the crankcase halves.

Separate the crankcase halves (a

special tool is not required).

The crankshaft has a snug fit in the

crankshaft bearing.

NOTE!

Note the guide sleeves between

the crankcase halves so they

are not lost!

Lift out the crankshaft.

Remove the crankcase gasket.

Lift out the crankshaft out of the clutch

side’s crankcase half (a special tool is

not required).

Remove the crankcase gasket.

Summary of Contents for 333R

Page 1: ...Workshop manual 333R 335R English ...

Page 2: ......

Page 36: ...34 4 Centrifugal clutch ...

Page 40: ...38 5 Angle gear ...

Page 50: ...48 6 Cylinder and piston ...

Page 60: ......

Page 61: ......

Page 62: ...2005W23 115 00 92 26 ...