6

45

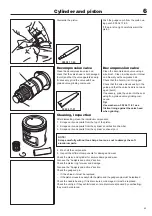

Cylinder and piston

Analysis and actions

Experience tells us that piston or cylinder failure due to manufacturing errors are ex-

tremely rare.

The reason is usually due to other factors, which is evident from the following.

Note the reasons for the breakdown, repair the damage and take the actions required to

prevent the same thing happening again.

Insuffi cient lubrication

The piston has small to medium size score marks usually in front of the exhaust port. In

extreme cases heat development can be so great that material from the piston smears

along the piston skirt and even in the cylinder bore.

Generally the piston ring is undamaged and moves freely in the ring groove

There can also be scores on the inlet side of the piston.

Cause:

• Incorrect carburettor setting. Recom-

mended max. speed exceeded.

• Incorrect oil mixture in the fuel.

• Too low octane fuel.

Action:

Check and change the carburettor setting.

Change the fuel.

Change to a higher octane petrol.

Cause:

• Incorrect oil mixture in the fuel.

• Too low octane fuel.

• Air

leaks.

Cracked fuel hose.

Leaking inlet gaskets.

Cracked distance piece or inlet

manifold.

• Air leakage in engine body.

Leaking crankshaft seals.

Leaking cylinder and crankcase

gaskets.

• Poor

maintenance.

Dirty

cooling

fi

ns on the cylinder.

Blocked air intake on the starter.

Blocked spark arrestor mesh in

the muf

fl

er.

For the best results we recommend Husqvarna two-stroke oil or ready-mixed fuel that is

specially developed for air-cooled two-stroke engines.

Mixing ratio: 1:50 (2%).

If Husqvarna two-stroke oil is not available another good quality two-stroke oil can be

used.

Mixing ratio: 1:33 (3%) or 1:25 (4%).

The piston ring starts to stick or is completely stuck in its groove and has therefore not

been able to seal against the cylinder wall, which has resulted in further, intensive tem-

perature increases in the piston

Seizure scores along the entire piston skirt on the inlet and exhaust sides.

Small to medium size scores primarily in the

middle of the exhaust port.

Medium to deep scores along the entire

piston skirt on the exhaust side.

Action:

Change to a fuel with the correct oil mix-

ture.

Change to a higher octane petrol.

Replace damaged parts.

Replace leaking gaskets and shaft seals.

Clean the cooling

fi

ns and air intake.

Clean or replace the spark arrestor mesh.

Summary of Contents for 345FR

Page 1: ...Workshop manual English 545RX 545FR 545FX 545FXT 545RX 545RXT 345FR ...

Page 2: ......

Page 16: ...2 14 Electrical system ...

Page 52: ...6 50 Cylinder and piston ...

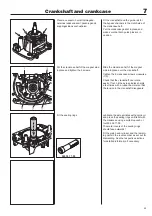

Page 58: ...7 56 Crankshaft and crankcase ...

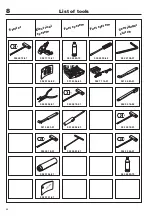

Page 62: ...8 60 List of tools ...

Page 65: ......

Page 66: ...2012W12 115 48 40 26 ...