English

– 11

GENERAL SAFETY PRECAUTIONS

General rules

•

Only use cutting equipment recommended by us!

See instructions under the heading Technical data.

•

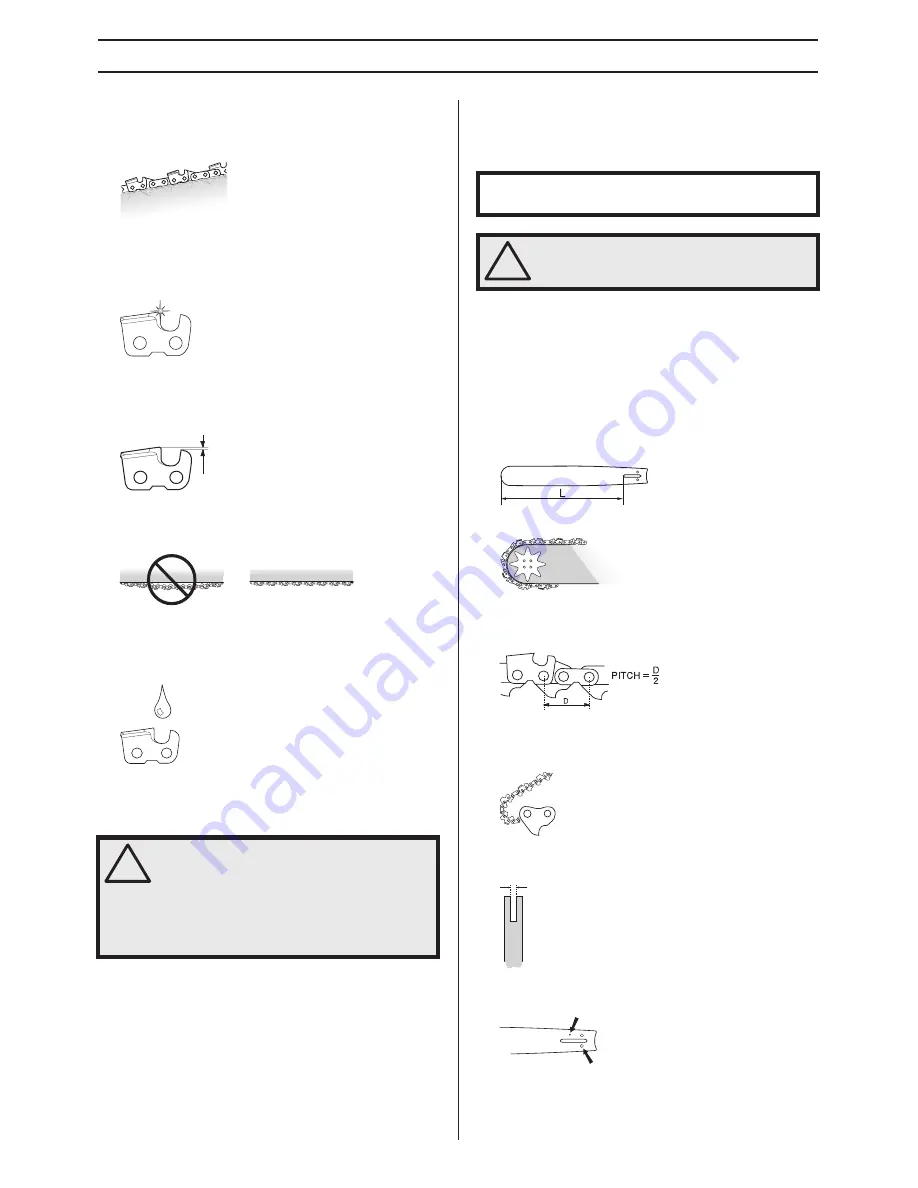

Keep the chain’s cutting teeth properly sharpened!

Follow our instructions and use the recommended file

gauge.

A damaged or badly sharpened chain increases

the risk of accidents.

•

Maintain the correct depth gauge setting! Follow our

instructions and use the recommended depth gauge

clearance.

Too large a clearance increases the risk of

kickback.

•

Keep the chain properly tensioned!

If the chain is slack

it is more likely to jump off and lead to increased wear on

the bar, chain and drive sprocket.

•

Keep cutting equipment well lubricated and properly

maintained!

A poorly lubricated chain is more likely to

break and lead to increased wear on the bar, chain and

drive sprocket.

Cutting equipment designed to reduce

kickback

The only way to avoid kickback is to make sure that the

kickback zone of the bar never touches anything.

By using cutting equipment with ”built-in” kickback reduction

and keeping the chain sharp and well-maintained you can

reduce the effects of kickback.

Bar

The smaller the tip radius the lower the chance of kickback.

Chain

A chain is made up of a number of links, which are available

in standard and low-kickback versions.

Some terms that describe the bar and chain

To maintain the safety features of the cutting equipment, you

should replace a worn or damaged bar or chain with a bar and

chain combinations recommended by Husqvarna. See

instructions under the heading Technical Data for a list of

replacement bar and chain combinations we recommend.

Bar

•

Length (inches/cm)

•

Number of teeth on bar tip sprocket (T).

•

Chain pitch (inches). The spacing between the drive links

of the chain must match the spacing of the teeth on the bar

tip sprocket and drive sprocket.

•

Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch and

the number of teeth on the bar tip sprocket.

•

Bar groove width (inches/mm). The groove in the bar must

match the width of the chain drive links.

•

Chain oil hole and hole for chain tensioner. The bar must

be matched to the chain saw design.

!

WARNING! Faulty cutting equipment or the

wrong combination of bar and saw chain

increases the risk of kickback! Only use the

bar/saw chain combinations we recommend,

and follow the filing instructions. See

instructions under the heading Technical

data.

IMPORTANT! No saw chain design eliminates the danger of

kickback.

!

WARNING! Any contact with a rotating saw

chain can cause extremely serious injuries.

Summary of Contents for 385XPR

Page 42: ... z RH 6 z RH 6 ...

Page 43: ......