4

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) Utility knife

(1) Tire pressure gauge

(1) Pair of pliers

(1) 9/16" wrench

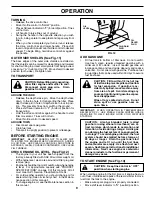

OPERATOR’S POSITION (See Fig. 1)

When right or left hand is mentioned in this manual, it

means when you are in the operating position (standing

behind tiller handles).

Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use

the correct tools as necessary to insure proper tightness.

FRONT

OPERATOR’S

POSITION

LEFT

RIGHT

FIG. 1

(1) Hairpin Clip

(1) Carriage Bolt

3/8-16 UNC x 1 Grade 5

(1) Center Locknut

3/8-16 UNC

(1) Handle Lock Lever

(1) Flat Washer 13/32 x 1 x 11 Gauge

CONTENTS OF HARDWARE PACK

(2) Handle Locks

(1) Pivot Bolt

3/8-16 UNC Grade 5

Extra Shear Pins & Clips

ASSEMBLY

Summary of Contents for 500RTT

Page 1: ...500RTT Owner s Manual ...

Page 27: ...27 SERVICE NOTES ...