18

8. Maintenance

■

FUEL FILTER

When you mount or dismount the fuel filter, be

careful not to damage the rubber packing. A

damaged rubber packing or insufficient mounting of

the fuel filter will cause fuel to leak.

Check how heavily the fuel filter is clogged from the

fueling port of the fuel tank every 25 hours of use.

If the fuel filter is clogged with dust, empty the fuel tank,

take the fuel filter out, and clean it with a brush, etc.

If the clogging of the fuel filter cannot be removed or the

fuel filter is damaged, replace it with a new one.

Part No.: T1154-85100

If the fuel filter is clogged, the engine rotation speed

might not increase, or rotation fluctuations might occur.

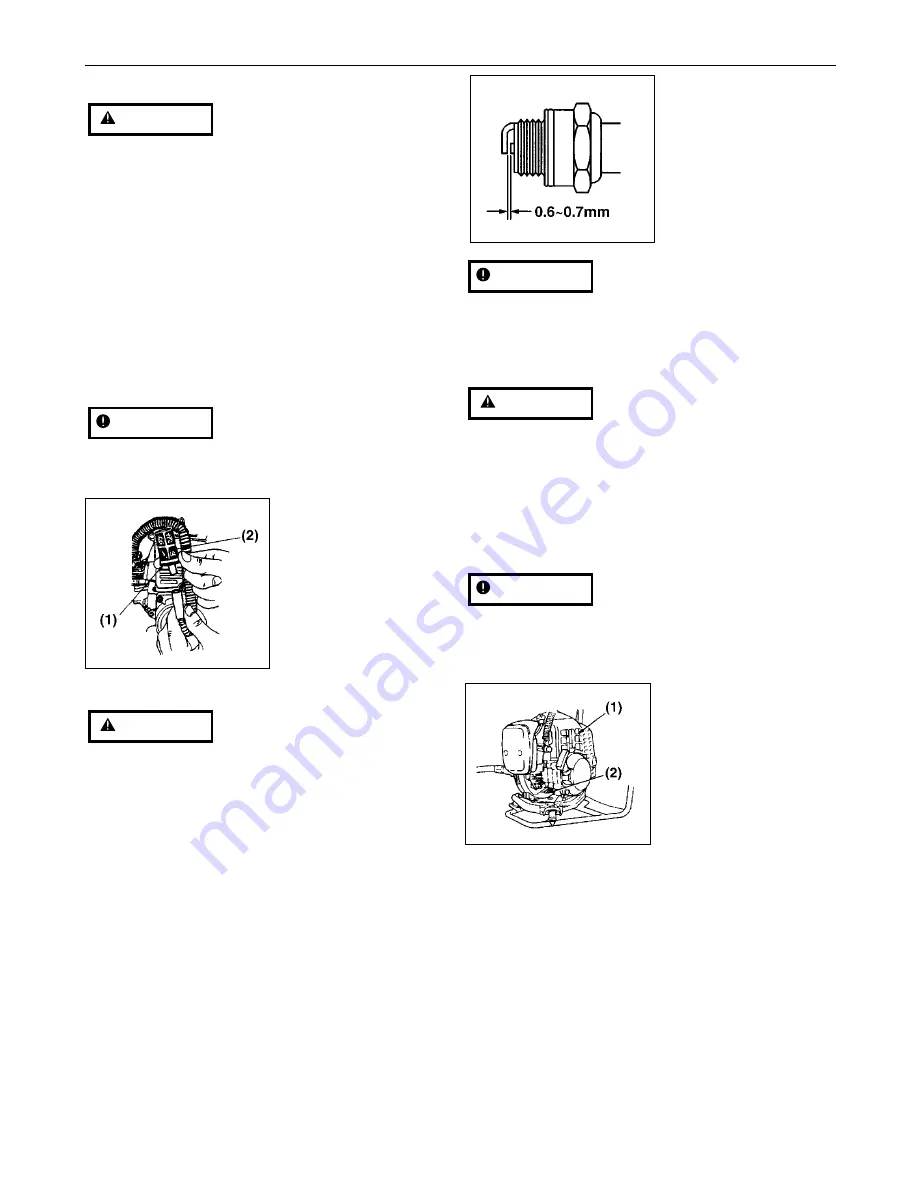

(1) Rubber packing

(2) Fuel filter

■

SPARK PLUG

Do not touch the spark plug with bare hands

immediately after stopping the engine. The spark

plug is still so hot and might cause burns.

Take out the spark plug, check the electrodes, and if

contaminated, clean them with a wire brush, etc. every

25 hours of use.

When mounting the spark plug, screw the plug in with

your fingers, and then tighten it with the plug wrench

supplied as a standard accessory.

The spark gap should be adjusted to 0.6 to 0.7 mm.

[Tightening torque]

9.8 to 11.8 N-m

(100 to 120 kgf-cm)

Designated spark plug

Champion: RCJ-6Y

NGK: BPM7A

WARNING

IMPORTANT

WARNING

If you use the plug wrench to start tightening the spark

plug, the thread might become damaged.

■

AIR COOLING VENT

Do not put any waste into the intake air-cooling vent

while the machine is in operation. It might touch the

rotating part, causing danger.

Check the intake air-cooling vent and the cooling fin of

the cylinder, and remove any dirt attached thereto every

25 hours of use.

If any waste or dirt is jammed between the intake air-

cooling vent and the cylinder fin, the engine might

overheat, causing trouble.

(1) Cylinder fin

(2) Intake air-cooling

vent

■

GEAR CASE

Supply lubricating grease to the gear case every 25

hours of use.

Designated grease

Lithium-based heat-resistant grease (#2)

[How to supply grease]

1. Remove the blade and the blade rest plate.

2. Remove the plug beside the gear case, and pour tube

grease from the plug hole.

3. Stop supplying the grease when all the old grease

has been pushed out from the shaft connecting hole

IMPORTANT

WARNING

IMPORTANT

MA6

MA5

MA4

Summary of Contents for 532RBS

Page 22: ......

Page 23: ......

Page 24: ...Original instructions 2010 11 01 1153989 26 www husqvarna com ...