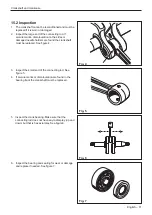

13.1 Assembling

1. Replace damaged parts.

2. Assemble the gear head in the opposite sequence

as set out for dismantling. See figure 6.

3. Fit the bearings on their respective axles. It is easier

if the bearings are heated to approx. 100°C.

Note: Do not forget the circlip holding the bearing on the

input axle. Make sure the bearings bottom in their seats.

4.

Heat the gearbox to approx. 150°C and first lift the

output axle in position and then the input axle. Make

sure the bearings bottom in their seats.

5. Mount the circlips and make sure they lie correctly in

their grooves.

6. Rotate the axles and make sure that they rotate

easily without a tendency for the cogwheels to seize.

Fill the gearbox with special grease (See Service

tools, pos. 15). Wipe any excess grease from the

joint between the shaft and the gear head before the

gear is fitted to prevent it from turning around the

shaft.

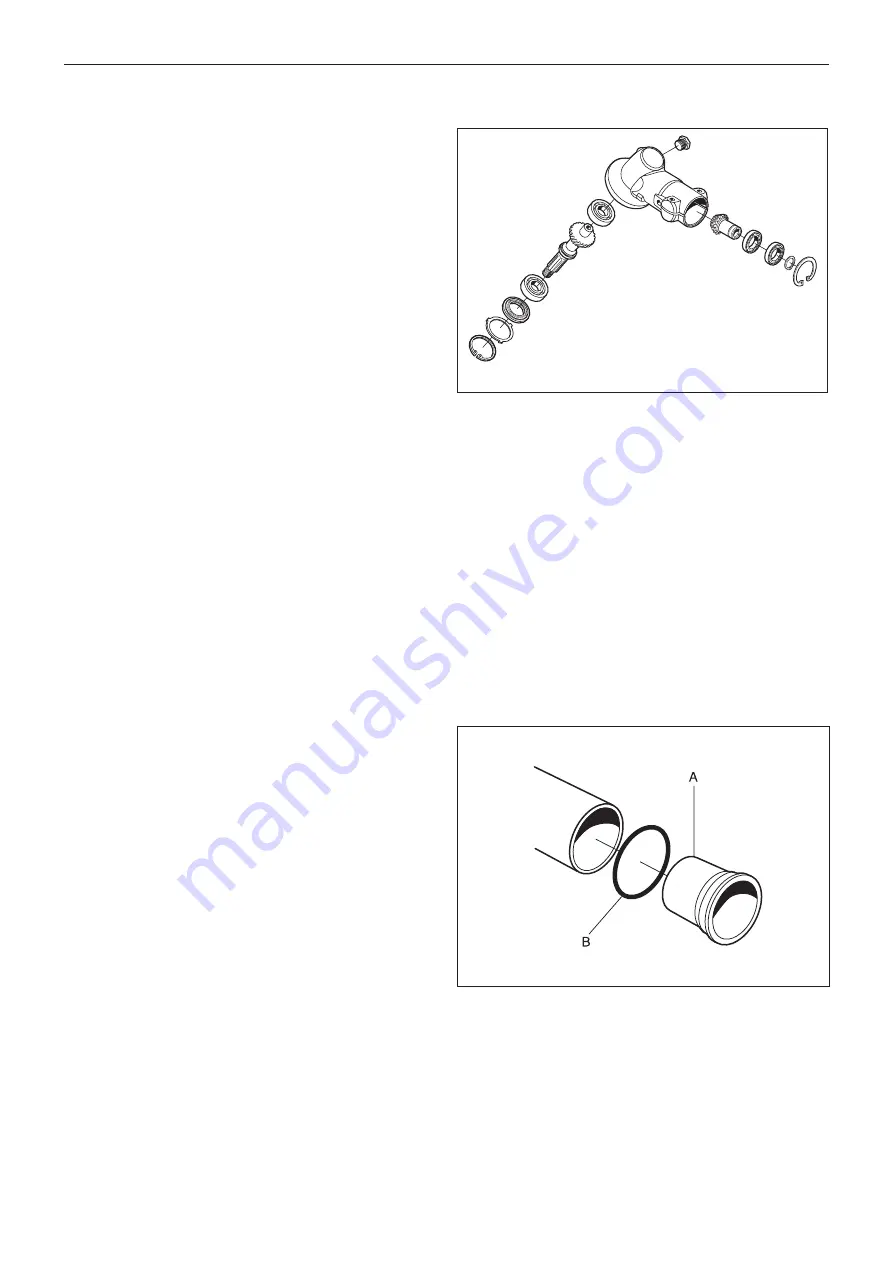

7.

Pry away the plastic sleeve (A) and the O-ring (B) on

the shaft using a knife. See figure 7.

8.

When fitting, a new O-ring must be used. To avoid

damage from the sharp edges of the slits in the gear

housing, the following assembly procedure is

recommended:

• Slide the O-ring B onto the plastic sleeve.

• Place the plastic sleeve A in the tube unit.

• Slide the shaft into position.

Lubricate the drive axle with grease (See Service tools,

pos. 16) when assembling.

Gear head

Fig. 6

Fig. 7

56 – English

Summary of Contents for 545FX AT

Page 1: ...Workshop manual English 545RXT AT 545FX AT 545FXT AT 545FX 545FXT 545RX 545RXT ...

Page 2: ......

Page 79: ...English 79 ...

Page 80: ...2018 10 04 115 88 11 26 ...