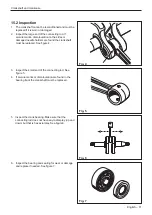

7. Use a long-nosed pliers to remove the G circlip from

the gudgeon pin. Keep your thumb over the circlip to

prevent it from flying out. See figure 4.

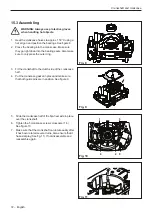

8. Push the gudgeon pin from the piston using a punch

See Service tools, pos. 17.

14.2 Cleaning and inspection

CAUTION! The soft aluminium parts can

get damaged. Remove carefully with a tool

that is not too sharp when removing carbon

deposits.

See figure 6.

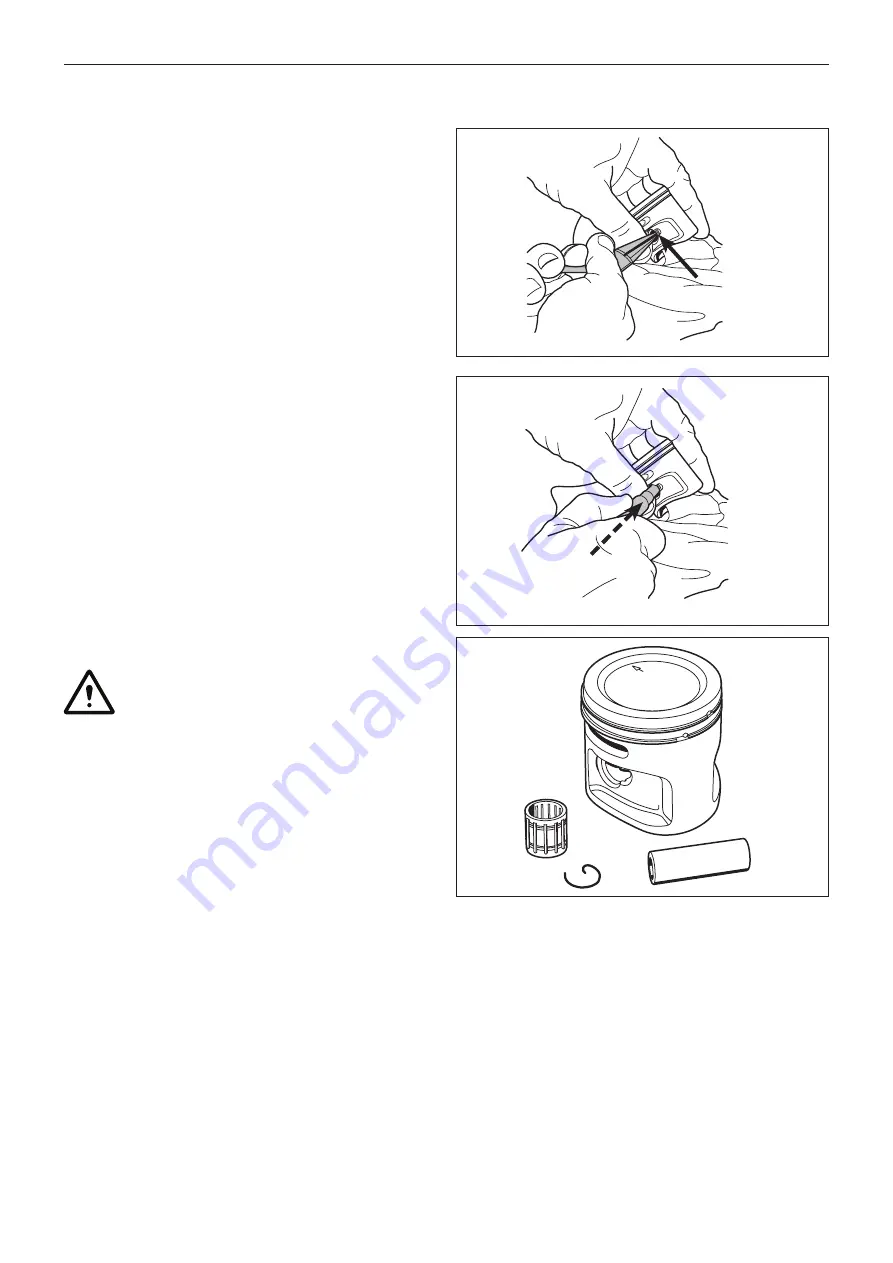

After dismantling, clean the individual components:

• Remove carbon deposits from the top of the piston,

the combustion chamber of the cylinder and the

exhaust and transfer ports port of the cylinder.

• Clean all the components.

Examine the different components for damage and wear:

• Inspect the piston and cylinder for seizure damage

and wear. Also see “14.5 Analysis and actions” on

• Inspect the piston ring for wear and damage. Also

see the “Analysis and actions” section.

• Inspect the gudgeon pin. If it has blued, it must be

replaced. If the piston moves too easily, replace both

the piston and the gudgeon pin.

• Inspect the needle bearing. Replace If it is

discoloured or damaged.

• Inspect the circlips. Replace if they have cracks or

are discoloured.

Cylinder and piston

Fig. 4

Fig. 5

Fig. 5

58 – English

Summary of Contents for 545FX AT

Page 1: ...Workshop manual English 545RXT AT 545FX AT 545FXT AT 545FX 545FXT 545RX 545RXT ...

Page 2: ......

Page 79: ...English 79 ...

Page 80: ...2018 10 04 115 88 11 26 ...