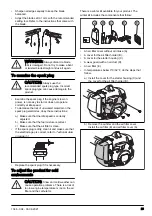

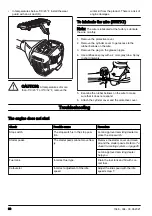

3. Rub the plastic bag to supply the oil equally across

the foam air filter.

4. Push the unwanted oil out of the foam air filter while

in the plastic bag.

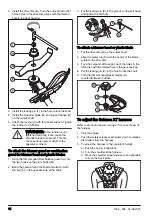

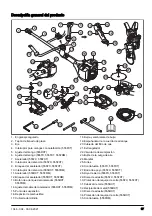

Bevel gear

The bevel gear is filled to ¾ with grease at the factory.

Before use, make sure that the grease level has not

changed. Use Husqvarna special grease if it is

necessary to fill up. Do not change the grease in the

bevel gear. Let servicing personnel do the repair of the

bevel gear.

To lubricate the bevel gear

1. Remove the cutting equipment.

2. Put the product with the grease plug at its highest

position.

3. Remove the grease plug.

4. Look into the grease plug hole and turn the drive

shaft. The grease level (A) must be in level with the

top of the gear cogs (B).

A

B

5. If the grease level is too low fill the bevel gear with

Husqvarna bevel gear grease. Fill slowly and turn

the drive shaft as you apply the bevel gear grease,

stop at the correct level (B).

CAUTION:

An incorrect quantity of

grease can cause damage to the bevel

gear.

6. Install the grease plug.

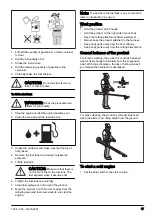

Drive shaft

Lubricate the drive shaft at an interval of 3 months. Let a

service agent help you if you are not sure about the

procedure.

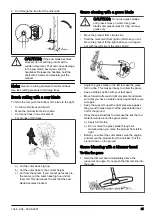

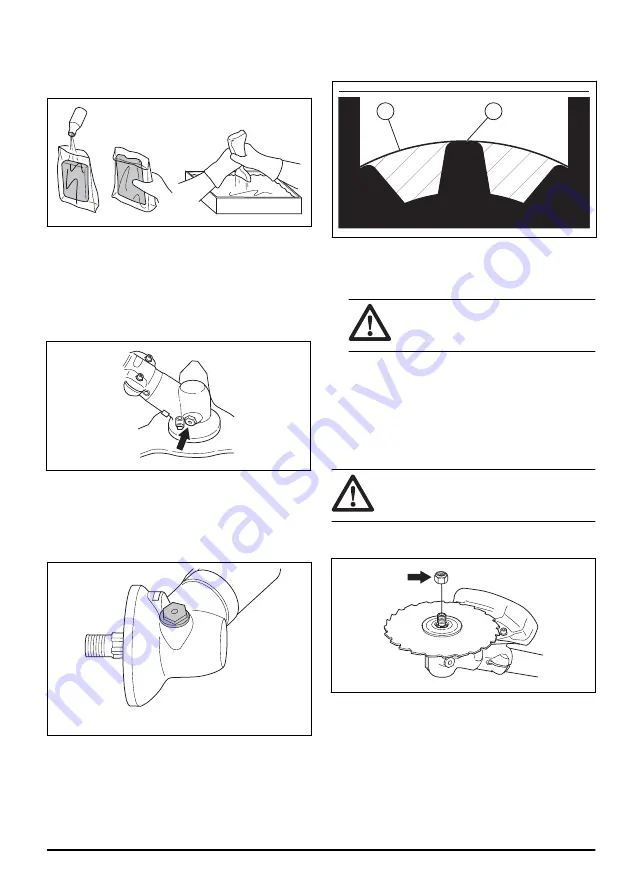

To attach and remove the locknut

WARNING:

Stop the engine, use

protective gloves and be careful around the

sharp edges of the cutting attachment.

Use the locknut to attach some types of cutting

attachments. The locknut has a left thread.

1346 - 004 - 03.06.2021

27

Summary of Contents for 555FRM

Page 111: ...1346 004 03 06 2021 111 ...