20

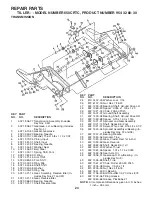

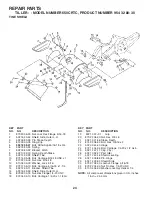

REPAIR PARTS

TILLER - - MODEL NUMBER 650CRTC, PRODUCT NUMBER 954 32 80-30

HANDLE ASSEMBLY

KEY PART

NO. NO. DESCRIPTION

21 532 18 11-27 Handle

23 532 08 67-77 Screw, Hex Washer Hd. Slotted

#10-24 x 1/2

24 532 00 94-84 Clip

26 532 15 92-31 Cable, Clutch

27 873 90 04-00 Nut Hex Flange 1/4-20 Unc

29 873 73 10-00 Nut, Keps #10-24 UNC

30 532 10 41-64 Tie, Cable

31 532 15 06-96 Bolt, Pivot

33 872 14 04-04 Bolt, Carriage 1/4-20 UNC x 1/2

37 532 10 26-04 Grip, Bar, Control

41 532 10 27-44 Clamp, Bar, Control

KEY PART

NO. NO. DESCRIPTION

1 532 18 06-34 Control, Throttle

2 532 00 92-66 Grip, Handle

4 532 15 92-28 Bar Assembly, Control

6 532 18 06-76 Panel, Control

8 871 19 10-08 Screw, Truss Hd. #10-24 UNC x 1/2

10 532 12 47-97 Grip, Handle

11 532 12 47-88 Clip, Hairpin

12 532 08 13-28 Bolt, Shoulder

13 532 10 93-35 Handle, Shift

14 532 10 93-13 Grommet, Rubber

15 532 10 93-37 Rod, Shift

16 872 11 06-08 Bolt, Carriage 3/8-16 x 1 Gr. 5

17 532 10 92-29 Lock, Handle

18 873 68 06-00 Nut, Crownlock 3/8-16 Unc

19 819 13 16-11 Washer 13/32 x 1 x 11 Ga.

20 532 10 92-28 Lever, Lock, Handle

NOTE:

All component dimensions given in U.S. inches.

1 inch = 25.4 mm