25

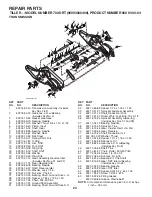

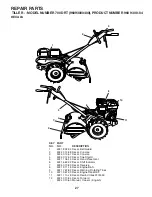

REPAIR PARTS

TILLER - - MODEL NUMBER 700 DRT (96093000400), PRODUCT NUMBER 960 93 00-04

TINE SHIELD

2

31

1

29

29

15

1

11

11

12

12

13

14

14

24

23

26

27

22

21

20

19

11

12

16

11

12

25

33

32

16

3

4

4

3

7

7

8

9

5

23

23

28

24

18

6

5

6

5

5

12

11

10

tine_shield_22a_in

KEY PART

NO. NO. DESCRIPTION

KEY PART

NO. NO. DESCRIPTION

NOTE:

All component dimensions given in U.S. inches.

1 inch = 25.4 mm

1 873 90 05-00 Nut, Lock Hex Flange 5/16-18 unc

2 532 16 29-52 Shield, Side, Outer L. H.

3 532 00 83-93 Pin, Stake, Depth

4 812 00 00-35 Ring, Klip

5 532 18 08-47 Bolt Rdhd Sqnk 5/16-18 x 3/4

6 532 00 83-94 Spring

7 532 00 83-92 Bracket, Latch

8 532 10 92-30 Spring, Depth Stake

9 532 40 38-89 Shield, Tine

10 872 14 05-08 Bolt 5/16-18 x 1

11 873 22 05-00 Washer, Lock 5/16

12 810 04 05-00 Nut, Hex 5/16-18

13 872 11 05-10 Bolt, Carriage 5/16-18 x 1-1/4

14 532 12 43-43 Bracket, Shield Tine

15 532 16 29-53 Shield, Side, Outer R.H.

16 873 90 04-00 Nut, Hex Flange 1/4-20

18 872 04 04-10 Bolt, Carriage 1/4-20 x 1-1/4 Gr. 5

19 532 10 27-01 Grip

20 873 22 06-00 Nut, Hex 3/8-16

21 532 10 21-56 Stake, Depth

22 874 93 06-32 Bolt, Hex 3/8-16 x 2

23 532 00 44-40 Hinge

24 872 14 04-04 Bolt, Carriage 1/4-20 x 1/2

25 532 00 67-12 Cap, Vinyl

26 532 10 92-27 Pad, Idler

27 532 12 50-16 Shield, Leveling

28 532 12 05-88 Pin, Hinge

29 532 40 39-60 Shield, Side

31 532 40 39-87 Stake, Drag

32 873 22 04-00 Nut, Fin, Hex 1/4-20 unc

33 810 04 04-00 Washer Lock Hvy Helical 1/4

Summary of Contents for 700DRT

Page 1: ...700DRT Owner s Manual ...