10

The operation of any snow thrower can result

in foreign objects thrown into the eyes, which

can result in severe eye damage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any ad just -

ments or repairs. We recommend standard safe ty glasses

or a wide vision safety mask worn over spectacles.

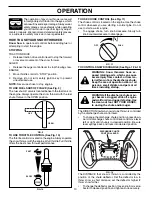

HOW TO USE YOUR SNOW THROWER

Know how

to operate all controls before adding fuel or

attempting to start the engine.

STOPPING

TRACTION DRIVE

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

AUGER

• Release the auger control lever to stop throwing snow.

ENGINE

1. Move throttle control to “STOP” position.

2. Remove (do not turn) safety ignition key to prevent

unauthorized use.

NOTE:

Never use choke to stop engine.

TO USE FUEL SHUT-OFF VALVE (See Fig. 9)

The fuel shut-off valve is located beneath the fuel tank on

the engine. Always op er ate the snow thrower with the fuel

shut-off valve in the OPEN position.

OPERATION

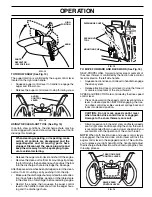

TO CONTROL SNOW DISCHARGE (See Figs. 12 & 13)

WARNING: Snow throwers have ex-

posed rotating parts, which can cause

severe injury from contact, or from ma-

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: If the discharge chute or au-

ger become clogged, shut-off en gine

and wait for all moving parts to stop. Use

the clean-out tool, NOT YOUR HANDS,

to un clog the chute and/or auger.

The DIRECTION in which snow is to be thrown is controlled

by the discharge chute control lever.

• To change the discharge chute position, press down-

ward on discharge chute control lever and move lever

left or right until chute is in desired position. Be sure

lever springs back and locks into desired position.

TO USE THROTTLE CONTROL (See Fig. 10)

The throttle control is located on the engine. Always op er ate

the snow thrower with the engine at full throttle. Full throttle

offers the best snow thrower performance.

TO USE CHOKE CON TROL (See Fig. 11)

The choke con trol is located on the en gine. Use the choke

control when ev er you are starting a cold en gine. Do not

use to start a warm en gine.

• To engage choke, turn knob clockwise. Slowly turn

knob counterclockwise to disengage.

DISCHARGE CHUTE

CONTROL LEVER

The DISTANCE that snow is thrown is controlled by the

position of the chute defl ector. Set the defl ector low to

throw snow a short distance; set the defl ector higher to

throw snow farther.

• To change the defl ector position, loosen knob, move de-

fl ector to desired position and tighten knob securely.

FIG. 10

FIG. 9

FIG. 12

FIG. 11

FULL

OFF

SLOW

FAST

OPEN

OFF

Summary of Contents for 8524STE

Page 1: ...8524STE Owner s Manual ...