5

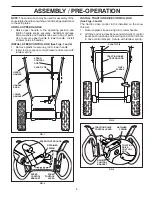

ASSEMBLY / PRE-OPERATION

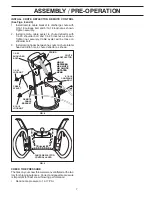

SPEED CON TROL ROD

SPEED

CONTROL

BRACKET

RETAINER

SPRING

SPEED

CONTROL

LEVER

FIG. 2

NOTE:

The multi-wrench may be used for assembly of the

chute rotator head to snow thrower and making ad just ments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle to the operating position and

tight en handle knobs securely. Additional carriage

bolts, washers and handle knobs are in bag of parts.

Use to secure upper handle to lower handle. Install

in lower holes in handles.

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

2. Insert rod into speed control bracket and secure with

retainer spring.

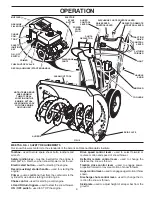

INSTALL TRACTION DRIVE CONTROL ROD

(See Figs. 3 and 4)

The traction drive control rod is installed on the snow

thrower.

1. Remove plastic tie securing rod to lower handle.

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rod into hole

in drive control bracket. Secure with retainer spring.

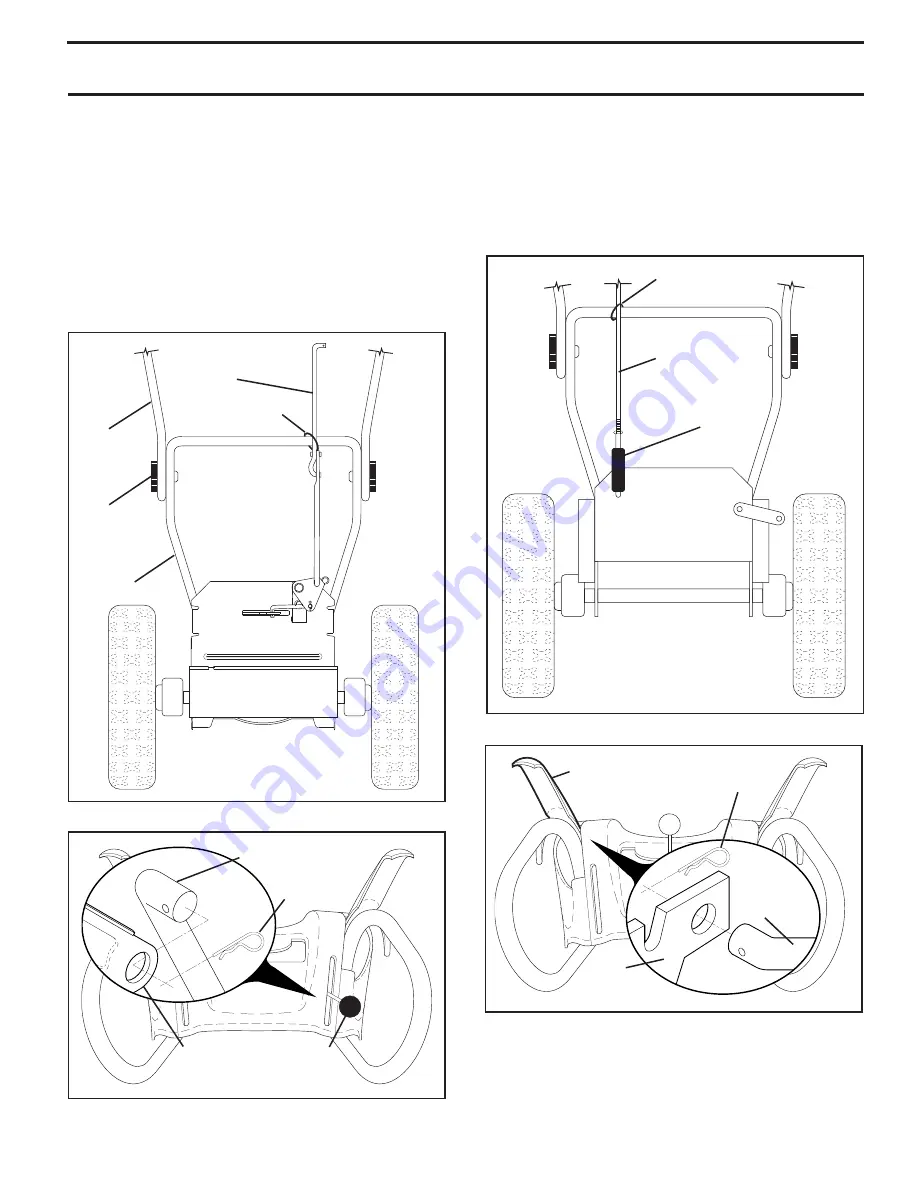

TRACTION

DRIVE

CON TROL

ROD

DRIVE

CONTROL

BRACKET

RETAINER

SPRING

TRACTION DRIVE

CON TROL LEVER

FIG. 4

TRACTION DRIVE

CONTROL ROD

VINYL

SLEEVE

FIG. 3

PLASTIC TIE

SPEED

CONTROL

ROD

HANDLE

KNOB

LOWER

HANDLE

PLASTIC TIE

UPPER

HANDLE

FIG. 1

Summary of Contents for 924HV

Page 21: ...21 SERVICE NOTES ...

Page 26: ...26 SERVICE NOTES ...

Page 27: ...27 SERVICE NOTES ...

Page 28: ...07 27 2011 SR ...