2

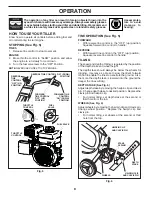

OPERATION

• Do not allow hands, feet, or other body parts or cloth-

ing near the rotating tines or any other moving part.

The tines begin to rotate once the engine/motor is

started and the activating device is engaged. The tines

may momentarily rotate after the activating device is

released.

• Exercise extreme caution when crossing gravel sur-

faces. Stay alert for hidden hazards or traffic.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug (or disconnect)

the cord for electric products), thoroughly inspect the

machine for any damage, and repair the damage before

restarting and operating the machine.

• Exercise caution to avoid slipping or falling.

• If the machine should start to vibrate abnormally, stop

the engine (motor) and check immediately for the cause.

Vibration is general a warning sign of trouble.

• Stop the engine (motor) when leaving the operating

position, before unclogging the tines, and when making

any repairs, adjustments, and inspections.

• Stop the engine (motor) when leaving the machine

unattended.

• Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Disconnect

the cord on electric motors.

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Never operate the machine without proper shields and

guards or other safety protective devices in place.

• Do not overload the machine capacity by attempting

to till or cultivate too deep at too fast a rate.

• Never operate the machine at high transport speeds

on hard or slippery surfaces.

• Never allow bystanders near the machine, especially

small children.

•

Use only attachments and accessories approved by the

manufacturer of the machine (such as wheel weights,

counterweights, and the like).

• Never operate the tiller without good visibility or light.

• Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

• Use extreme caution when reversing or pulling the

machine towards you. To avoid getting pinned against

a structure, ensure adequate distance before revers-

ing near a wall or fence. For machines with powered

reverse drive capability, familiarize yourself with the

operation of the Emergency Stop Control. It provides

a secondary means of stopping power to the tines and

wheel drive in an emergency.

• Do not change the engine governor settings or over

speed the engine.

•

Start the engine or switch on the motor carefully accord-

ing to instructions and with feet away from the tines.

SAFETY RULES

SAFE OPERATION PRACTICES FOR POWERED WALK-BEHIND ROTARY

TILLERS AND HAND-SUPPORTED CULTIVATORS

TRAINING

• Read, understand, and follow all instructions on the

machine and in the manual(s) before starting. Be

thoroughly familiar with the controls and the proper

use of the equipment. Know how to stop the machine

and disengage the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to op er ate the equipment without proper

instruction.

• Keep the area of operation clear of all persons, par-

tic u lar ly small children, and pets.

PREPARATION

• Thoroughly inspect the area where the equipment is

to be used and remove all foreign objects.

• Disengage all clutches and shift into neutral before

starting the engine (mo tor).

• Do not operate in shorts or open toed shoes. Wear

proper Personal Protective Equipment (PPE) at all

times, such as gloves, proper footwear, and eye pro-

tection.

• Use extension cords and receptacles as specified by

the manufacturer for all machines with electric drive

motor or electric starting motors.

• Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by the manufacturer).

SAFE HANDLING OF GASOLINE:

• To avoid personal injury or property damage, use ex-

treme care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

• Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

• Use only an approved gasoline container.

• Never remove gas cap or add fuel with the engine

running.

• Allow engine to cool before refueling.

• Never refuel the machine indoors.

•

Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as on a water

heater or other appliance.

• Never fill containers inside a vehicle of on a truck or

trailer bed with a plastic liner. Always place containers

on the ground away from your vehicle before filling.

• Remove gas powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment with a portable container,

rather than from a gasoline dispenser nozzle.

•

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock open device.

•

If fuel is spilled on clothing, change clothing immediately.

• Never overfill fuel tank. Replace gas cap and tighten

securely.

•

If fuel is spilled, do not attempt to start engine but move

the machine away from the area of spillage and avoid

creating any source of ignition until fuel vapors have

dissipated.

Summary of Contents for 96083001100

Page 19: ...19 SERVICE NOTES ...

Page 20: ...05 09 18 SR Printed in U S A ...