13

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE ASSISTANCE -

REPLACEMENT PARTS

To retain the quality of your mower, use genuine

HUSQVARNA replacement parts only. Contact

your local HUSQVARNA dealer for parts and

service assistance. For the correct part or

information for your particular mower, always

mention model and serial number. We recom-

mend returning your mower to an authorized

HUSQVARNA dealer on a yearly basis for

inspection and addition of any new devices

which might upgrade the performance and

safety of your mower. For engine parts and

service, look in the yellow pages for the engine

manufacturer's dealers under the heading

engines - gasoline.

WARNING

BEFORE PERFORMING SERVICE ON THE

MOWER TURN ENGINE OFF, CLOSE THE

FUEL VALVE, AND ALLOW ENGINE TO

COOL. DISCONNECT THE SPARK PLUG

WIRE. IF THE MOWER IS TO BE RAISED

OR TILTED, MAKE SURE TO SECURE THE

MOWER IN PLACE.

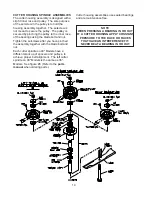

MODULE SYSTEM

The interlock modules function is to prevent the

engine from starting if the blade and/or traction

systems are engaged. It also causes engine

shutdown if the operator falls from, or attempts

to leave the operator position while the blades or

traction drives are engaged. After the engine

starts, the operator must hold either the left or

right O.P. lever down before engaging the

blades or shifting the transmission into gear. If

neither O.P. lever is held the engine will stop.

INTERLOCK SAFETY SYSTEM

Check the function of the safety electrical

system on a regular basis.

1. Engine must kill if blades are engaged without

O.P. levers held down.

2. Engine must kill if transmission is taken out of

neutral without holding down O.P. levers.

NOTE

ALL MOWERS SHOULD BE TILTED WITH

THE CARBURETOR SIDE UP

CAUTION

DO NOT BYPASS THE INTERLOCK SWITCHES

THEY ARE FOR YOUR PROTECTION! CHECK

THE OPERATOR PRESENCE SYSTEM DAILY

ALONG WITH THE TRACTION DRIVE SWITCHES

AND BLADE SWITCH FOR PROPER OPERATION.

REPAIR IMMEDIATELY IF A

PROBLEM IN THE SYSTEM IS FOUND. DO NOT

OPERATE MOWER IN A DAMAGED CONDITION.

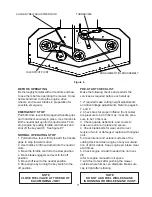

BLADES

If blades are in good condition, sharpen at an

angle of 22 to 28 degrees about 2-1/2" in from

the tips.

NOTE

AFTER SHARPENING, CHECK BLADES FOR

PROPER BALANCE, IF NEEDED CORRECT BAL-

ANCE TO PREVENT EXCESSIVE VIBRATION

CUTTING DECK SERVICE

If mower is cutting improperly, check the follow-

ing:

1. Ground speed - too fast for proper cutting.

Shift to a lower gear.

2. Engine speed - Increase engine speed.

3. Cutting height - too low for ground/grass

conditions. Adjust to higher cut.

4. Blade spacers - not positioned properly on all

blade shafts. Visually inspect and replace or

adjust as necessary.

5. Front casters - spacers not in correct rela-

tionship with rear axle. Adjust as necessary.

6. Belt slippage - causing bad cutting pattern or

uneven cut. Adjust belt tension

7. Tire pressure - uneven tire pressure can

cause an uneven cut from one side of the deck

to the other. Equalize tire pressure.

3. Engine must not start unless blades are off

and transmission is in the neutral position.

4. Do not operate the mower if the interlock

safety system allows operating or starting in any

unsafe condition.