15

MAINTENANCE

Pump belt

Check belt every 100 hours for excessive wear.

To replace belt. Relieve tension on the deck belt

and remove deck belt from clutch. See deck belt

instructions on previous page. Loosen bolt on

the clutch tie down and rotate out of the way.

Using a 1/2” drive ratchet inserted into the

square hole in the pump idler arm relieve the

tension on the pump belt and remove belt. To

reinstall belt. Swing pump idler pulley out toward

engine to route belt around it. Then route belt

around right side pulley first as you are looking

up from the underside of machine. Reinstall

idler spring and use the ratchet to rotate idler so

the belt may be installed all the way around the

last pulley.

Lubrication

See service decal under foot plate for service

points and maintenance intervals. Clean grease

zerks thoroughly before greasing. See engine

manual for engine service. FIG - 16

Tire pressure

Check every 25 hours. All four tires require 15

psi.

FIG - 16

Winter storage

To prepare the machine for storage. Clean the

machine, especialy under the deck. Touch-up

the paint or spray the underside of deck with a

light coat of oil.

Inspect the machine for damage and loose

hardware.

Change the oil.

Drain the fuel system or add stabilizer to fuel.

Make sure to run the machine after to circulate

stabilizer throughout system.

Remove the plugs and add 1 tablespoon of oil in

each cylinder. Install plugs and crank the engine

two or three revolutions.

Grease all zerks.

Remove battery and store inside and protect it

from freezing temperatures.

Caster Wheels

Check every 200 hours. Lift front of unit off of

ground so caster wheels can rotate freely.

Tighten caster bolt then back off 1/2 turn. Check

that wheel rotates freely. If wheel does not rotate

freely back the caster bolt off in 1/4 turn incre-

ments until wheel rotates freely.

Fuel filter

Replace every 500 hours or annually. In ex-

tremely dirty conditions replacement may need

to be at shorter intervals.

Summary of Contents for 968999204

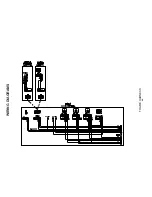

Page 20: ...20 WIRING DIAGRAMS CONSOLE HARNESS SCHEMATIC ...

Page 22: ...22 WIRING DIAGRAMS FRAME HARNESS ...

Page 23: ...23 ...

Page 24: ......