21

OPERATION

Key Switch

Throttle

Choke

Blade

Engagement

FIG - 9

NOTE:

Associated choke on some models.

Hour Meter

Hour Meter

The hour meter displays the total operating time

and reminds of service intervals.

The meter will indicate “CHG OIL” for engine oil

and “SVC” for general service at preset intervals.

The hour meter will reset itself at predetermined

times.

Key switch is located on the console. Used to start

the machine. NOTE: Do not run the starter for more

than 5 seconds at a time. If the engine will not start,

wait about 10 seconds before trying again. FIG - 9

Throttle Control

Throttle control is located on the console. Used to

control engine RPM. FIG - 9. Some models have

an intergated choke located on the throttle con-

trol. Choke position for these models is maximum

forward on the throttle control.

Parking Brake

Parking brake is located on the left side of the

machine and directly in front of the fuel tank. Pull

the lever back to engage the brake and push lever

forward to release the brake.

Key Switch

Blade Switch

Blade engagement switch located on the console

is engaged by pulling up on the switch and pushed

down to disengage. FIG - 9.

Choke Control

Choke control is located on the console. To choke

engine pull knob push to release. FIG -9.

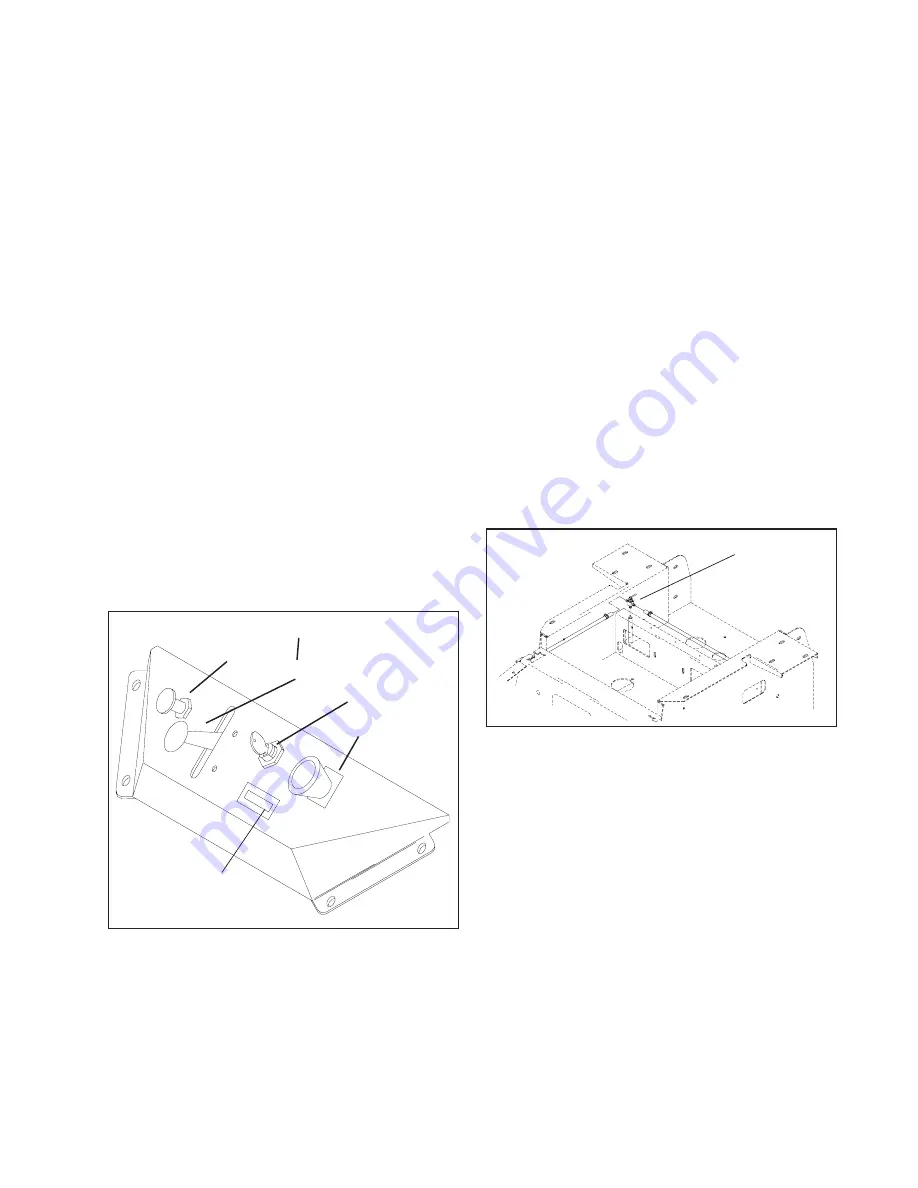

Fuel shut off valve is located at the right rear of the

seat. The valve has three positions a right tank, left

tank and center is the off position. FIG - 10.

Engine “CHG” will come on after the first ten (10)

hours of operation, and will stay on for one (1)

hour of operation before it will reset itself. It will

come on every 99 hours thereafter, and stay on

for five (5) hours of operation before resetting.

Mower “SVC” message will come on every 50

hours to remind to lubricate the unit, check blades

and fasteners, etc. This message will stay on for

two (2) hours of operation before resetting.

Fuel Shut Off

Fuel Valve

FIG - 10

Pump Release Valves

Pump release valves located at the right front cor-

ner of the pumps. Used to release the system so

the machine may be moved by hand when not

running. Tilt seat forward to gain access to the

pumps. Use a 5/8” wrench to open valve. NOTE:

Only rotate valve 1/4 turn to release system.

Summary of Contents for 968999207 / iZ5223KAA

Page 2: ...2 2004 Husqvarna All right reserved Beatrice NE Printed U S A ...

Page 28: ...28 WIRING DIAGRAMS ...

Page 29: ...29 WIRING DIAGRAMS ...

Page 30: ......