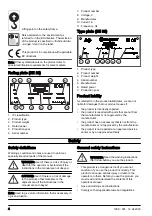

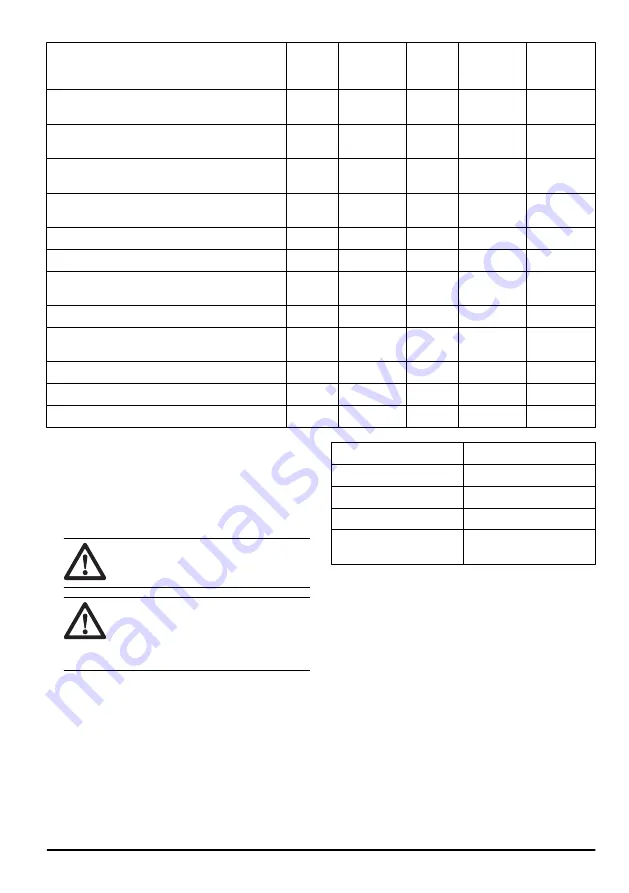

BE 30

Each

use

After the

first 20h

Each

50h

Monthly or

each 200h

Each 3

months or

each 300h

Do a check of the fuel level and the engine oil

level.

O

Do a check of the throttle control and the throttle

wire.

*

Examine the air filter. Clean the air filter if it is

necessary.

O

Clean the air filter. Replace the air filter if it is nec-

essary.

O

O

Replace the air filter.

O

Replace the engine oil.

O

O

O

O

Examine and clean the spark plug. Replace the

spark plug if it is necessary.

O

O

Do a check of the engine speed.

O

Drain the fuel and clean the fuel tank and the fuel

filter.

O

Clean and adjust the carburetor.

O

Clean the cylinder head.

O

Adjust the fuel valve.

O

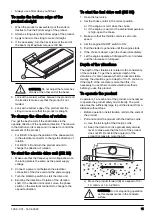

To clean the product

• Remove concrete from the surfaces of the product

after each operation before the concrete becomes

hard. Spray with concrete form oil or concrete

release agent.

• Use a high-pressure washer to clean the product.

CAUTION: Do not point the water

directly at the motor of an electric drive

unit.

CAUTION: Before you clean a fuel drive

unit with a high-pressure washer, put a

cover on the engine. No water must

come on the carburetor, the fuel tank or

the generator.

• Clean the external surfaces of the engine of a fuel

drive unit with water, but not a high-pressure washer.

• Clean the shafts but do not point the water at the

bearings.

• Tilt the product to clean the bottom side.

• Remove grease and oil from the handle.

Lubrication

It is necessary to replace the grease on model BE 20

each 5000 hours. Refer to the table.

BE 20

Type of bearing

6305.ZZ

SKF suffix

C3

FAG suffix

C3

Grease

TRIBOL 3030/100 WITH

T.G.O.A.-

The interval for lubrication of the bearings on model

BE 30 is each 1200 hours.

To replace the bearings

1. Remove the covers.

2. Make a note of the position of the eccentric weights.

3. Remove the nuts and the eccentric weights.

4. Remove the flanges and the rotor.

5. Remove the bearings from the flanges with a punch.

6. Clean the bearings with an applicable cleaning

agent.

7. Lubricate the bearings. Refer to

Lubrication on page

13

.

8. Make sure that the O-rings and seals are not

damaged. Replace damaged parts.

1299 - 001 - 14.04.2020

13