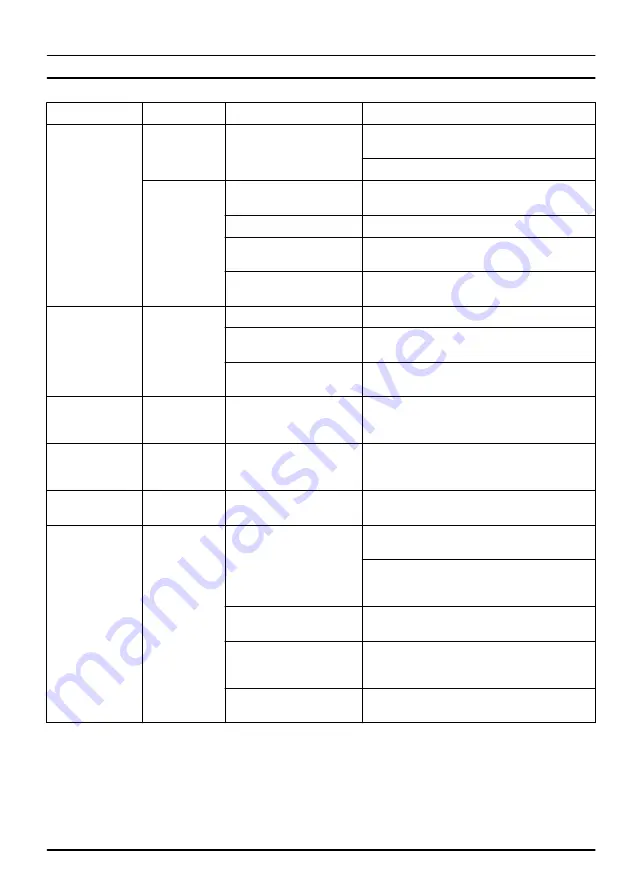

Troubleshooting

Problem

Drive unit

Cause

Solution

The product does

not start.

Electric.

There is no current.

Connect the power cord correctly to the electri-

cal connection on the product.

Do a check of the mains outlet.

Fuel.

The fuel level or oil level is

too low.

Fill fuel and oil to the correct level.

The fuel valve is closed.

Open the fuel valve.

The engine ON/OFF switch

is in the OFF position.

Set the engine ON/OFF switch to the ON posi-

tion.

The spark plug is worn or

not installed correctly.

Examine the spark plug. Replace it if it is neces-

sary.

The motor stops

after some mi-

nutes.

Electric.

The voltage is too high.

Do a check of the voltage of the power supply.

The motor protection is re-

leased.

The motor load is too high. Decrease the centri-

fugal force.

The circuit breaker is re-

leased.

Bad ground connection. Do a check of the con-

nectors and cables. Replace damaged parts.

The tension

screws cannot be

turned.

Electric and

fuel.

There is water from the

concrete in the product

sections.

Use penetrating oil on the tension screws.

The tension

screws are loose

or missing.

Electric and

fuel.

The tension screws are

worn.

Replace the tension screws.

The beam is not

straight.

Electric and

fuel.

The rubber bearings on the

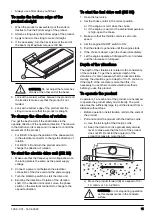

stretching screw are worn.

Replace the bearings.

The result of the

concrete surface

is unsatisfactory.

Electric and

fuel.

The drive unit is incorrectly

set.

Make sure that the position of the eccentric

weights is correct.

Do a check of the drive belt tension and the ten-

sion of the product sections. Adjust or replace if

it is necessary.

The product is too long for

the work area.

Adjust the work area or install a shorter beam to

the drive unit.

The rails are different at

each end of the product or

not applicable.

Adjust the rails.

There is too much concrete

in front of the product.

Monitor the height of the concrete during opera-

tion.

1299 - 001 - 14.04.2020

15