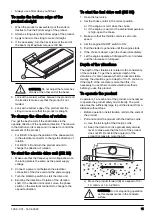

• Always use original accessories and spare parts.

Accessories and spare parts that are not approved

by the manufacturer, can cause serious injury or

death.

• Replace damaged, worn or broken parts.

• Only do the maintenance as given in this operator's

manual. Let an approved service center do all other

servicing.

• Remove all tools from the product before you start

the engine after maintenance. Loose tools or tools

attached to rotating parts can eject and cause injury.

• After maintenance, do a check of the vibration level

in the product. If it is not correct, speak to an

approved service center.

• Let an approved service center do servicing on the

product regularly.

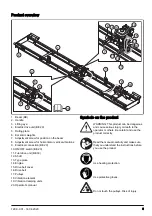

Assembly

Introduction

WARNING: Read and understand the safety

chapter before you assemble the product.

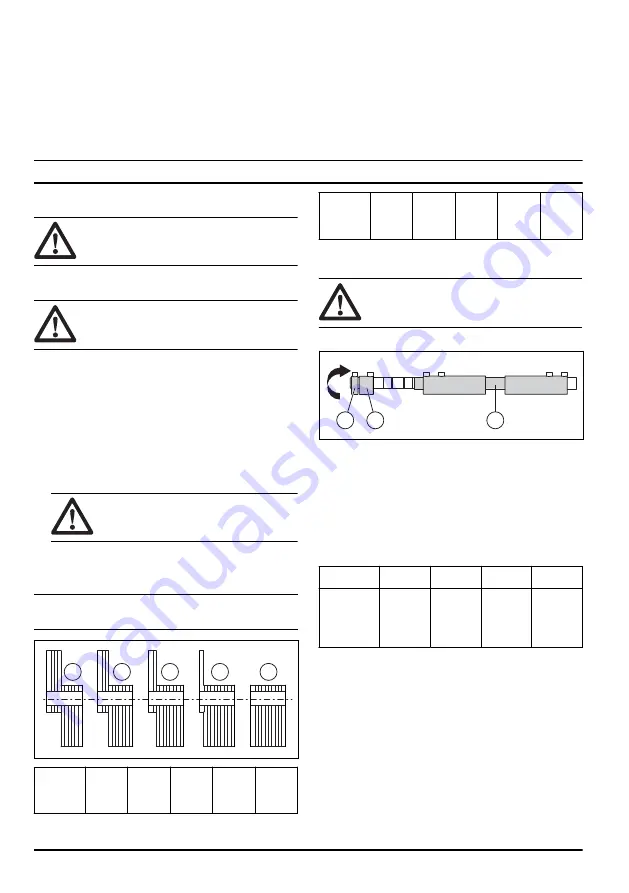

To adjust the centrifugal force (BE 20)

WARNING: Disconnect the power source

before you adjust the centrifugal force.

1. Remove the screws from the covers for the eccentric

weights. There is 1 cover on each side of the drive

unit.

2. Remove the covers for the eccentric weights.

3. Remove the nuts that hold the eccentric weights.

The available positions are identified in the table and

on the covers.

4. Turn the eccentric weights 180° to adjust the

centrifugal force.

CAUTION: Do the same adjustment at

each end of the drive unit.

5. Attach the eccentric weights.

6. Install the covers. Make sure that the cover seals are

in good condition.

Note: The centrifugal force is set at position 4 at the

factory.

5

4

3

2

1

Number

of

weights

1

2

3

4

5

Centrifu-

gal

force, N

920

1850

2770

3690

4620

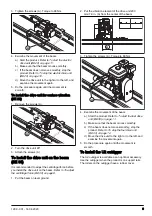

To adjust the centrifugal force (BE 30)

WARNING: To prevent accidental start, stop

the engine and remove the spark plug cap

before you adjust the centrifugal force.

1. Remove the cap.

C

B

A

2. Loosen the screws that hold the eccentric weights

(A) and (B).

3. Turn the eccentric weights (A) and (B) 180° to adjust

the centrifugal force.

4. Tighten the screws that hold the eccentric weights

(A) and (B).

5. Install the cap. Make sure that the O-rings are

installed correctly.

Weights

C

A+C

B+C

A+B+C

Centrifugal

force, N

@3600

min

-1

1920

2140

2400

2620

To install the drive unit on the beam

(BE 20)

It is recommended to adjust the centrifugal force before

you install the drive unit on the beam. Refer to

the centrifugal force (BE 20) on page 8

.

1. Put the beam on level ground.

2. Put the drive unit at the center of the beam.

8

1299 - 001 - 14.04.2020