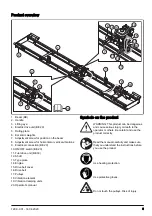

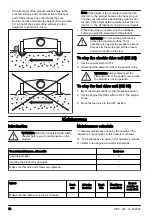

1. Install the brackets (A) to the beam with the supplied

screws and nuts.

B

A

2. Adjust the height and length of the extension arm

(B).

Note: The height between the lower edge of the

extension arm and the beam can be adjusted from

125 mm/6 in. to 250 mm/10 in. in 25 mm/1 in.

intervals. The length can be extended between 130

mm/5 in. and 500 mm/16 in.

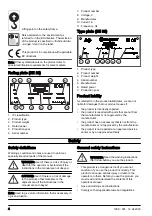

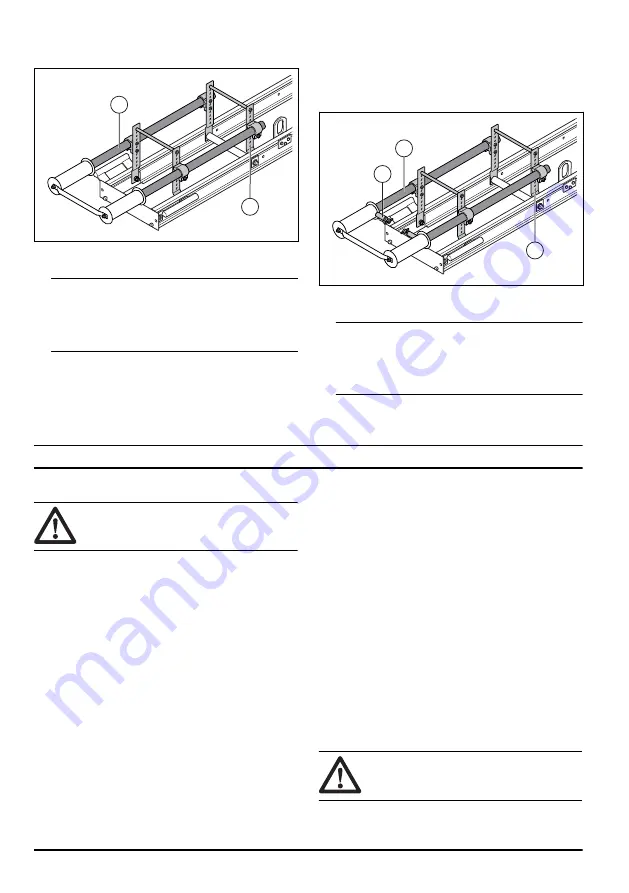

To install the U3 outrigger

The U3 outrigger is available as an optional accessory.

Use the outrigger when the product is on support rails.

The rollers on the outrigger have a rubber cover. The

outrigger has wheels that are attached to a shaft. The

shaft and the wheels lift the beam from the concrete

surface. This makes it easier to move the beam back

across the concrete surface.

1. Install the brackets (A) to the beam with the supplied

screws and nuts.

B

C

A

2. Adjust the height and length of the extension arm

(B).

Note: The height between the lower edge of the

extension arm and the beam can be adjusted from

125 mm/6 in. to 250 mm/10 in. in 25 mm/1 in.

intervals. The length can be extended between 130

mm/5 in. and 500 mm/16 in.

3. Adjust the height of the beam with the handles (C).

Operation

Introduction

WARNING: Read and understand the safety

chapter before you use the product.

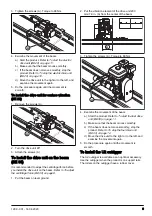

To do before you operate the product

(BE 20)

• Read the operator's manual carefully and make sure

that you understand the instructions.

• Do the daily maintenance. Refer to

schedule on page 12

.

• Make sure that the electrical connection and the

power cord on the product are not damaged.

• Make sure that the power cord can move freely

along the concrete surface during operation.

• Make sure that the bottom edge of the product is

straight. Refer to

To make the bottom edge of the

product straight on page 11

.

• Make sure that the rails are stable. Rails that are not

stable can cause the product to tilt or prevent correct

movement of the product.

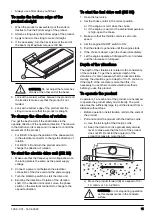

To do before you operate the product

(BE 30)

• Read the operator's manual carefully and make sure

that you understand the instructions.

• Read the engine manual that is supplied by the

engine manufacturer.

• Do the daily maintenance. Refer to

schedule on page 12

.

• Make sure that there is sufficient fuel in the fuel tank.

• Make sure that the bottom edge of the product is

To make the bottom edge of the

.

• Make sure that the direction of rotation of the shaft is

correct for the operation.

• Make sure that the rails are stable. Rails that are not

stable can cause the product to tilt or prevent correct

movement of the product.

To fill fuel

WARNING: Read and obey the instructions

.

• Close the fuel valve before you fill fuel.

10

1299 - 001 - 14.04.2020