• Always use a filter when you fill fuel.

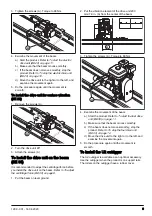

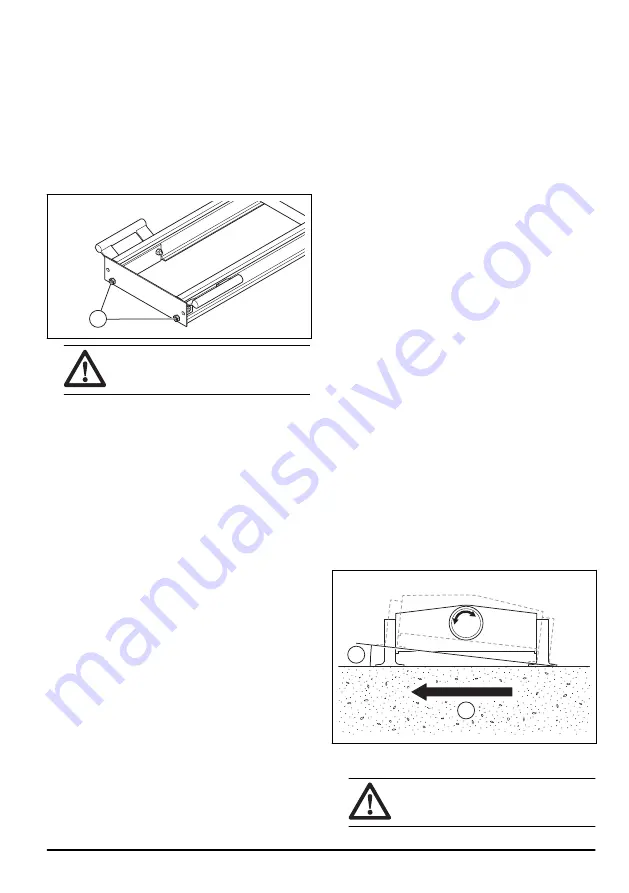

To make the bottom edge of the

product straight

1. When the product is assembled, put the ends on

trestles to free the bottom edge of the product.

2. Attach a string along the bottom edge of the product.

3. Apply tension to the string to make it straight.

4. If it is necessary, turn the hex screws at the end of

the beam (A). Maximum torque is 100 Nm.

A

CAUTION: Do not adjust the female hex

screws at the other end of the beam.

5. Look at the contact surface between the product and

the trestles to make sure that the product is not

twisted.

6. Look at the bottom edge of the product and the

string to make sure that the product is straight.

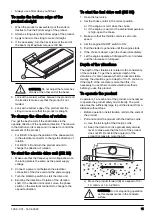

To change the direction of rotation

You get the best results if the shaft rotates in the

opposite direction of the operation direction. The tension

in the traction cords is kept and it is easier to control the

movement of the product.

• For BE 20: Change the position of the phase switch

in the electrical connector to change the direction of

rotation.

• For BE 30: Lift and turn the product around to

change the direction of rotation.

To start the electric drive unit (BE 20)

1. Make sure that the frequency and voltage shown on

the rating plate is the same as the power supply

voltage.

2. Connect a power cord between the electrical

connection of the drive unit and the power supply.

3. Turn the start/stop switch to start the drive unit.

4. Examine the direction of rotation of the vibration

shaft. If the direction is incorrect, move the phase

switch on the electrical connector to change to the

opposite direction.

To start the fuel drive unit (BE 30)

1. Open the fuel valve.

2. Set the choke control in the correct position.

a) If the engine is cold, close the choke.

b) If the engine is warm or the ambient temperature

is high, open the choke.

3. Make sure that the throttle control is set to idle

speed.

4. Set the engine ON/OFF switch to ON.

5. Pull the starter rope handle until the engine starts.

6. If the choke is closed, open the choke immediately.

7. Let the engine operate at idle speed for 2–3 minutes

and then increase to full speed.

Depth of the vibrations

The depth of the vibrations is related to the consistency

of the concrete. To get the maximum depth of the

vibrations, it is also necessary that the rails are stable.

Usually, the vibrations go to a depth of 10–15 cm/4–6 in.

If the depth of the concrete is more than this, it is

necessary to use other concrete vibration methods

before you use this product.

To operate the product

2 operators, 1 at each end of the product, are necessary

to operate the product safely and correctly. The work

area must be sufficiently large to pull the product from a

distance without stops.

• Before operation, install traction cords to the ends of

the product.

• Pull and control the product with the traction cords.

a) Use the full length of the traction cords.

b) Keep the traction cords approximately at waist

level, to make sure that the front of the product

does not lift. Do not let the angle (A) of the

product increase to more than 8°.

B

A

c) Move the product forward (B) at a speed of 0.5–

1.0 m/min. or 1.6–3.2 ft/min.

CAUTION: Do not stop during operation

as this causes marks in the concrete

surface.

1299 - 001 - 14.04.2020

11