wc_tx000640gb.fm

32

Maintenance

CRT 36

4.2

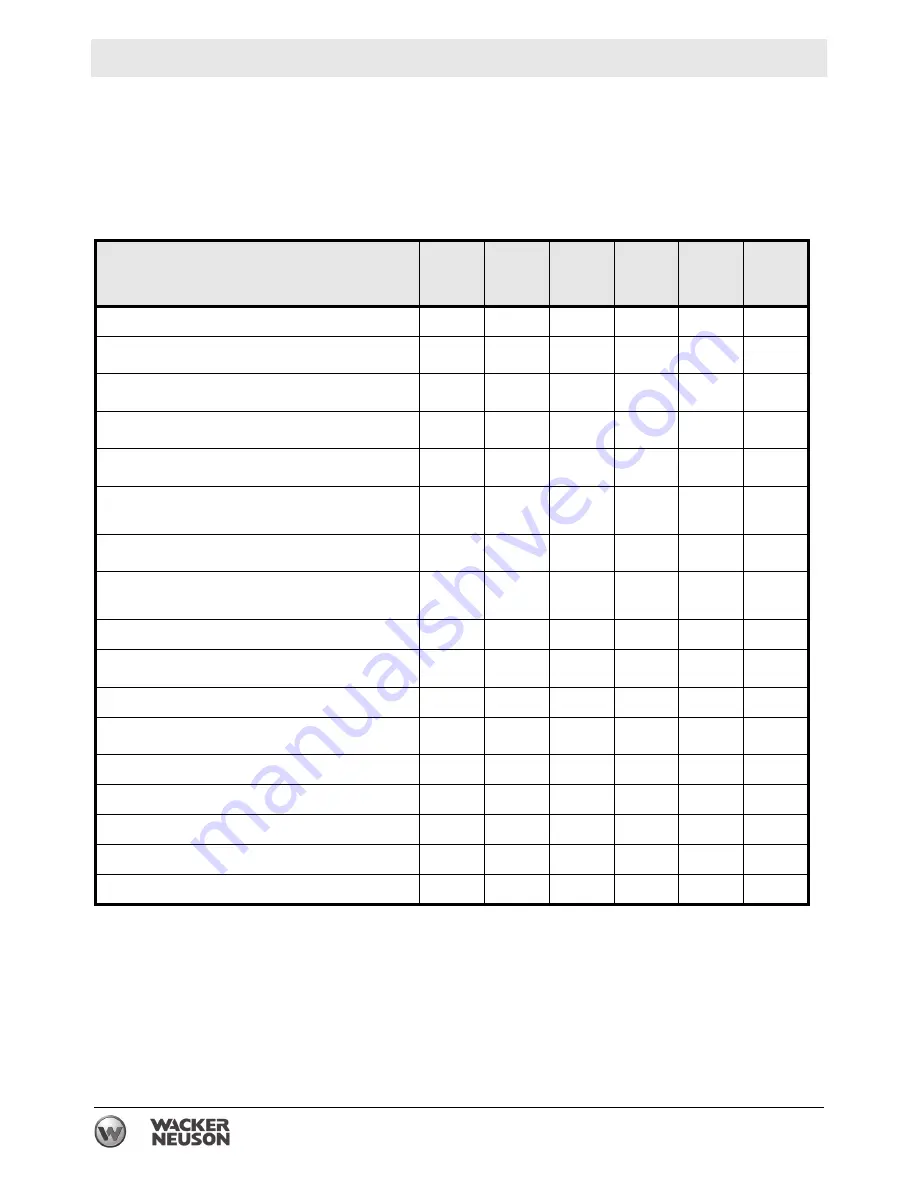

Periodic Maintenance Schedule

The table below lists basic machine maintenance. Tasks designated with check

marks may be performed by the operator. Tasks designated with square bullet

points require special training and equipment.

Refer to the engine operator’s manual for information on engine maintenance.

Daily

Every

20

hrs.

Every

50

hrs.

Every

100

hrs.

Every

200

hrs.

Every

300

hrs.

Grease trowel arms.

Check fuel level.

Check engine oil level.

1

Inspect air filter. Replace as needed.

Check external hardware.

Pressure wash all surfaces until free of

concrete.

2

Check oil level in gearboxes.

Grease gearbox, drive system and pitch posts

fittings.

Grease control linkage.

Check drive belt for wear.

Change engine oil.

3

Check fuel filter.

Clean and check spark plug.

Replace oil filter.

Replace spark plug.

Replace fuel filter.

Replace oil in gearboxes.

1

Check engine oil twice daily (every 4 hours).

2

Pressure wash immediately after use.

3

Change engine oil after first 20 hours of operation.

Summary of Contents for CRT 36-25

Page 4: ...CALIFORNIA Proposition 65 Warning wc_tx004643en fm 4 Notes ...

Page 8: ......

Page 17: ...CRT 36 Labels wc_si000378gb fm 17 2 Labels 2 1 Label Locations C D B J Z ...

Page 18: ...Labels CRT 36 18 wc_si000378gb fm BB AA ...

Page 23: ...CRT 36 Labels wc_si000378gb fm 23 Notes ...

Page 24: ...wc_tx000639gb fm 24 Operation CRT 36 3 Operation 3 1 Features and Controls ...

Page 54: ...wc_tx001324gb fm 54 Schematics CRT 36 7 Schematics ...

Page 56: ...wc_tx001324gb fm 56 Schematics CRT 36 Notes ...

Page 73: ...33 Notes 34 Notes ...