wc_si000970gb_FM10.fm

25

CRT48

Labels

F

WARNING

Hot surface

G

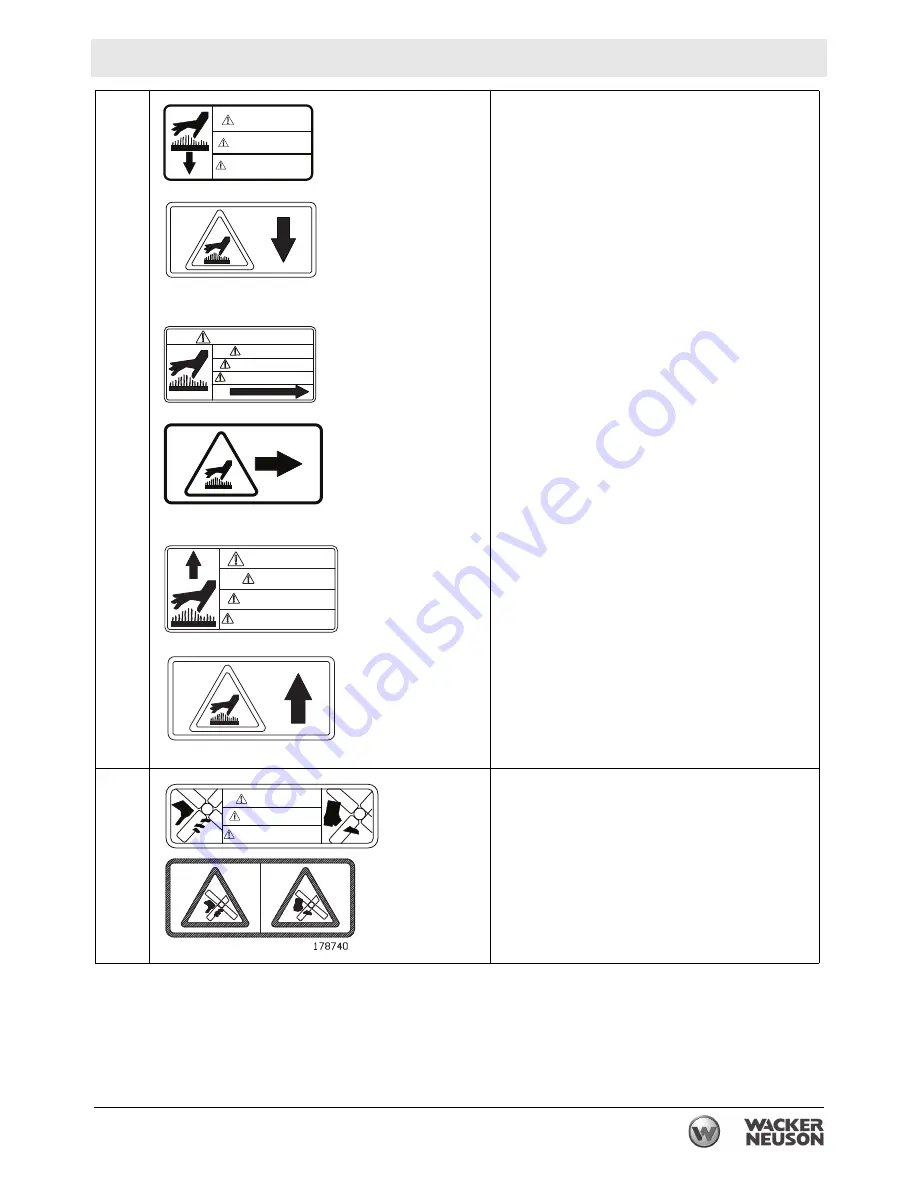

WARNING

Cutting hazard. Keep hands and feet away

from blades. Always replace blade guard.

117039

ADVERTENCIA

ADVERTENCIA

AVERTISSEMENT

AVERTISSEMENT

WARNING

WARNING

178713

178713

WARNUNG

WARNUNG

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

AVERTISSEMENT

AVERTISSEMENT

117037

117037

178732

178732

WARNING

WARNING

5200007832

5200007832

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNUNG

WARNUNG

5200007834

5200007834

111453

111453

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

WARNING

WARNING

Summary of Contents for CRT 48-35L

Page 4: ...CALIFORNIA Proposition 65 Warning wc_tx004643en fm 4 Notes ...

Page 8: ......

Page 12: ...Table of Contents CRT48 wc_bo5100022491_09TOC fm 12 ...

Page 21: ...wc_si000969gb_FM10 fm 21 CRT48 Safety Information Notes ...

Page 82: ...wc_td000668gb_FM10 fm 82 Technical Data CRT48 Notes ...

Page 111: ...33 Notes 34 Notes ...

Page 113: ...CRT48 Schematics wc_tx004197gb_FM10 fm 113 14 Schematics Notes ...

Page 120: ......