2

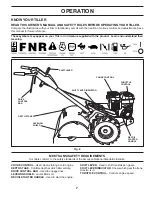

• Keep children and pets away.

• Do not overload the machine capacity by attempting

to till too deep at too fast a rate.

•

Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

• Never allow bystanders near the unit.

• Use only attachments and accessories approved by

the manufacturer of the tiller.

• Never operate the tiller without good visibility or light.

• Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

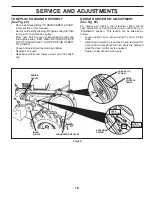

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

work ing condition.

• Check shear pins, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be

sure the equip ment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such

as hot water and space heaters, clothes dryers, and

the like. Allow the engine to cool before storing in any

enclosure.

• Always refer to the operator’s guide instructions for

im por tant details if the tiller is to be stored for an ex-

tended period.

- IMPORTANT -

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS OF

ATTRACTING ATTENTION TO IMPORTANT OR CRIT I CAL

IN FOR MA TION IN THIS MANUAL.

IMPORTANT:

USED TO ALERT YOU THAT THERE IS A

POS SI BIL I TY OF DAM AG ING THIS EQUIP MENT.

NOTE:

Gives essential information that will aid you to bet-

ter understand, incorporate, or execute a particular set of

instructions.

Look for this symbol to point out im-

por tant safety precautions. It means

CAUTION!!! BE COME ALERT!!! YOUR

SAFE TY IS INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it can-

not contact spark plug in order to pre-

vent ac ci den tal starting when setting

up, trans port ing, adjusting or making

re pairs.

SAFETY RULES

Safe Operation Practices for Walk-Behind Powered Ro ta ry Tillers

TRAINING

• Read the Owner’s Manual care ful ly. Be thor ough ly

fa mil iar with the controls and the proper use of the

equip ment. Know how to stop the unit and disengage

the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to op er ate the equipment without proper

instruction.

• Keep the area of operation clear of all persons, par-

tic u lar ly small children, and pets.

PREPARATION

• Thoroughly inspect the area where the equipment is

to be used and remove all foreign objects.

• Disengage all clutches and shift into neutral before

starting the engine (mo tor).

• Do not operate the equipment with out wearing ad e -

quate outer gar ments. Wear footwear that will im prove

footing on slippery surfaces.

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

•

Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

• Replace gasoline cap securely and clean up spilled

fuel before restarting.

• Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

• Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

rec om mend ed by manufacturer).

OPERATION

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when op er at ing on or cross-

ing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry pas sen gers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly in spect

the tiller for any damage, and repair the damage before

restarting and op er at ing the tiller.

• Exercise caution to avoid slipping or falling.

• If the unit should start to vibrate ab nor mal ly, stop the

engine (motor) and check immediately for the cause.

Vi bra tion is generally a warning of trouble.

• Stop the engine (motor) when leaving the operating

position.

•

Take all possible precautions when leav ing the ma chine

unattended. Disengage the tines, shift into neutral, and

stop the engine.

• Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Disconnect

the cord on electric motors.

• Do not run the engine indoors; exhaust fumes are

dangerous.

• Never operate the tiller without proper guards, plates,

or other safety protective devices in place.

WARNING

The engine exhaust from this product con-

tains chem i cals known to the State of Cal i -

for nia to cause cancer, birth defects, or other

reproductive harm.

Summary of Contents for CRT900

Page 1: ...Owner s Manual 532 43 95 06 CRT900 ...

Page 27: ...27 SERVICE NOTES ...