11

GENERAL

The warranty on this tiller/cultivator does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, the operator must main-

tain the tiller/cultivator as instructed in this manual. The follow

SERVICE DATES

SCHEDULE

Tighten All Screws and Nuts

After

first 2

Hours

Every

25

Hours

Every

75

Hours

Fill in dates as you

complete regular service

Before

Each

Use

Lubricate Transmission

Lubricate Tine Shaft

Clean and Re-Oil Air Cleaner Filter

Check Spark Plug

Cylinder Exhaust Ports

Before

Storage

SERVICE RECORDS

Drain Fuel

LUBRICATION

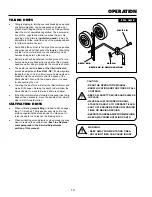

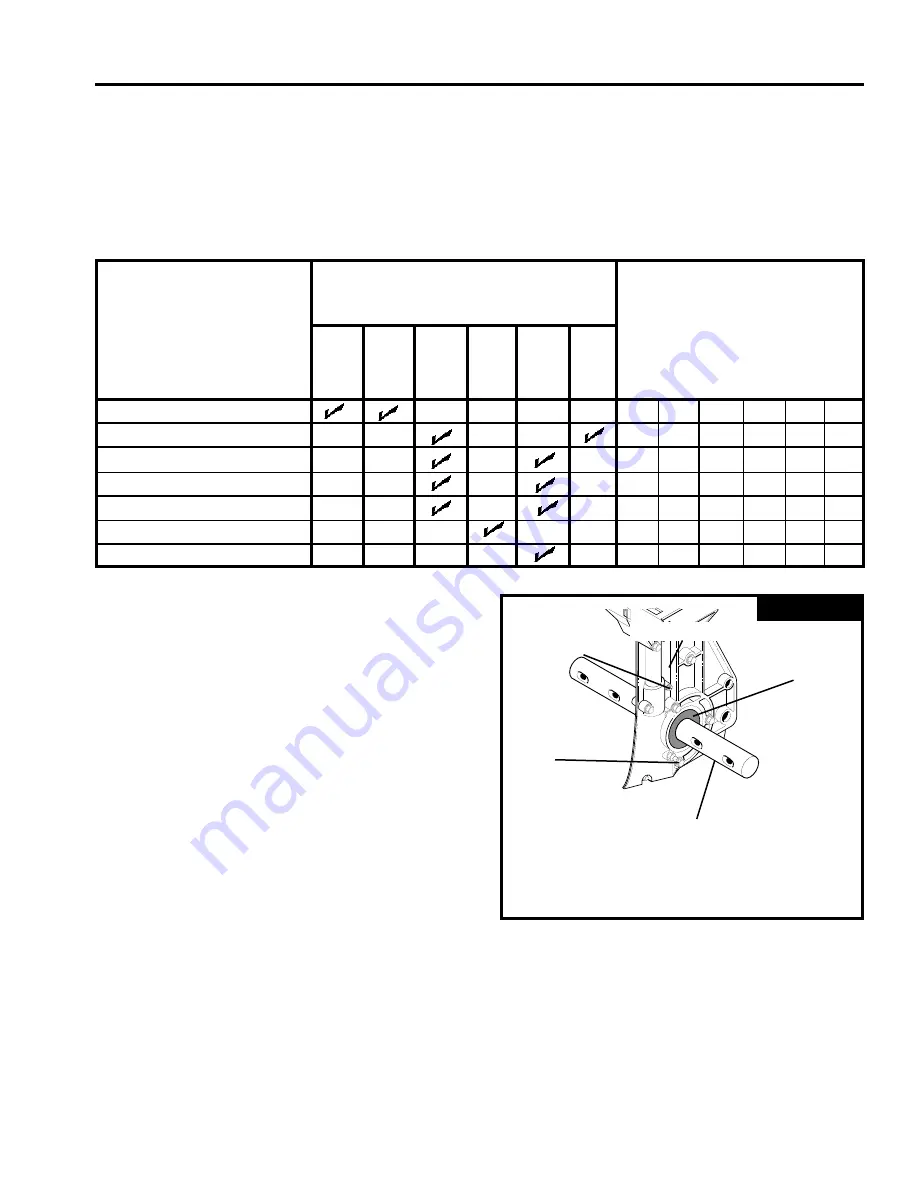

Every 25 hours and/or at the beginning of each season, the

gear box should be filled with lubricant. Tubes of gear lubricant

are available from most automotive supply stores. Use por-

table tool grease such as Lubriplate 630AA (Product No.

06787 - 1-3/4 oz. tube) or Lubriplate GR-132 (Product No.

15892 - 10 oz. tube). The tine shaft should have oil applied

before storage and after cleaning if the tiller/cultivator is

flushed with water. The following illustration is provided to

assist the operator properly maintain the tiller/cultivator.

CHECK TRANSMISSION GREASE LEVEL

●

Remove both left side tines (See Service and Adjust -

ments section) in this manual.

●

Remove the air vent screw (See FIG. 1-C.R.) from the top

left side of the transmission.

●

Using a grease gun, fill the transmission through the

grease fitting until the new grease begins to come out of

the air vent screw hole.

●

Reinstall the air vent screw.

●

Check the condition of the felt washer in the side of the

transmission at the tine shaft (See FIG. 1-C.R.). Re

place the felt washer if it is damaged (See Repair Parts

section in this manual).

●

Clean tine shaft, spread a few drops of oil on shaft in tine

replacement areas. Reinstall the tines.

●

Remove the right side tines. Check the felt washer for

damage, clean and oil the tine shaft. Reinstall the tines.

SERVICE RECOMMENDATIONS CHART

TINE SHAFT

(Oil the tine shaft before storage

and after cleaning if the

dethatcher/ cultivator is flushed

with water)

FELT

WASHER

TRANSMISSION

VIEW OF LEFT SIDE WITH TINES REMOVED

ing Service Recommendations Chart is provided to assist

the operator properly maintain the tiller/cultivator.

FIG. 1-C.R.

Before

Each

Season

GREASE

FITTING

(Lubricate the

gear box with

Lubriplate

630AA or

Lubriplate GR-

132)

AIR VENT

SCREW

MAINTENANCE