12

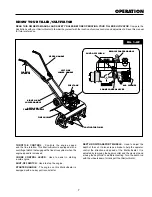

ENGINE

AIR CLEANER

The air cleaner filter should be cleaned and reoiled after 3

months or 25 hours of operation. Clean more often under dusty

conditions.

IMPORTANT:

The engine can be worn out in a very

short period of time if dirt or grit is allowed to

enter the engine.

To clean the air filter, do the following:

●

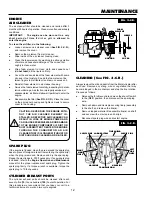

Loosen screws on air cleaner cover (See FIG. 2-C.R.)

and remove the cover.

●

Remove foam element from air cleaner.

●

Wipe inside of the air cleaner housing clean.

●

Clean the foam element by washing in a strong solution

of water and household detergent. Then rinse thor

oughly in clean water.

●

Wrap foam element in clean cloth and squeeze out

(do not twist) all the liquid until dry.

●

Cover the ends and side of the foam element with same

oil used in fuel mixture. Knead the foam element be

tween fingers to distribute oil and remove excess oil.

●

Reinstall foam element in air cleaner housing.

●

Service the foam element carefully, inspecting for deterio

ration or damage. A defective, improperly serviced, or

misassembled air filter will allow dirt particles to enter the

engine.

●

Reassemble the filter (See FIG. 2-C.R.). Place the cover

on the air cleaner housing and tighten screws to secure

cover to the housing.

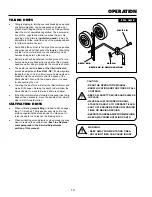

SPARK PLUG

If the engine is flooded, clean the area around the spark plug

base to prevent foreign material from entering the cylinder(s)

when the plug is removed. Remove and dry the spark plug.

Regap the electrodes to .030 if necessary. If a new spark plug

is needed, refer to the Engine Operation and Maintenance

manual for the proper replacement spark plug. Tighten the

spark plug firmly. If a torque wrench is available, torque the

spark plug to 15 foot-pounds.

CYLINDER EXHAUST PORTS

The cylinder exhaust ports should be cleaned after each

seventy-five (75) to one hundred (100) hours of operation. For

this procedure we recommend that you take your unit to a

technician trained to work on two cycle engines.

OFF

ON

C

H

O

K

E

OFF

FULL

HOUSING

COVER

SCREWS

FOAM

ELEMENT

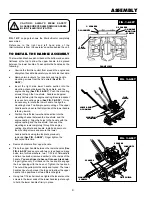

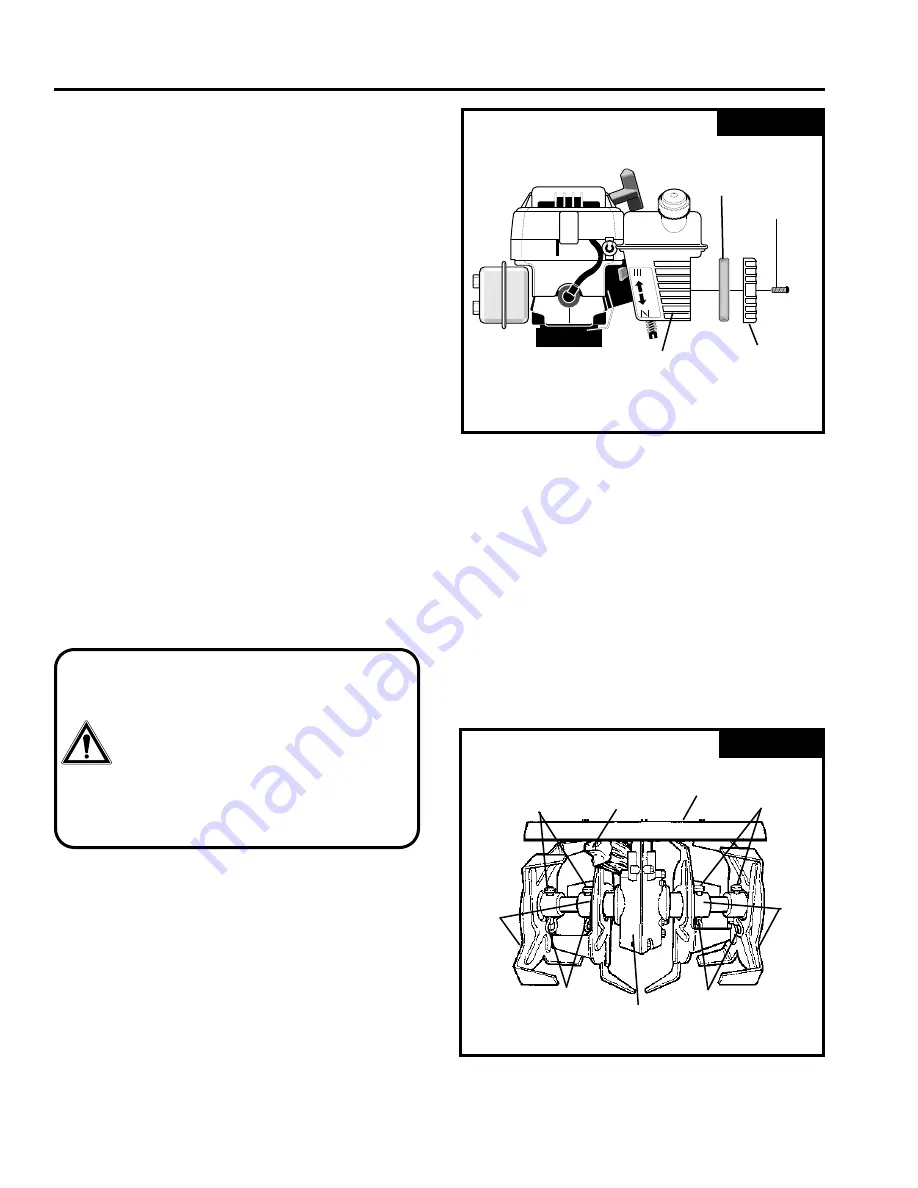

HAIRPINS

HAIRPINS

CLEVIS PINS

LEFT

SIDE

TINES

TRANSMISSION

TINE SHIELD

LODGED ITEM

CLEVIS PINS

RIGHT

SIDE

TINES

FIG. 2-C.R.

FIG. 3-C.R.

CLEANING (See FIG. 3-C.R.)

Always remove the dirt and debris from the tiller/clutivator after

each use. Remove any string, wire or vegetation that may

become lodged in the mechanism and stop the tine rotation.

Proceed as follows:

●

Release the throttle control and move the shut-off switch

to the (OFF) position, then disconnect the spark plug

wire.

●

Remove hairpin and clevis pin securing tine(s) assembly

to the shaft and remove the tine(s).

●

Remove lodged material. Reassemble tine(s) on shaft

and secure with a clevis pin and hairpin.

●

Reconnect spark plug wire and restart engine.

MAINTENANCE

CAUTION: NEVER RUN THE ENGINE WITH-

OUT THE AIR CLEANER ELEMENT IN-

STALLED. A DEFECTIVE AIR CLEANER CAN

RESULT IN LOSS OF ENGINE POWER AND

CAN CAUSE EXCESSIVE WEAR OR DAMAGE

TO THE ENGINE COMPONENTS IF DIRT OR

DUST IS PERMITTED TO ENTER THE ENGINE

THROUGH THE CARBURETOR. AN AIR

CLEANER THAT IS CLOGGED WITH DUST OR

DIRT SHOULD BE CLEANED AND RE-OILED.