20

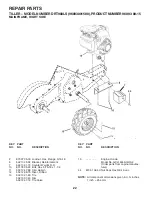

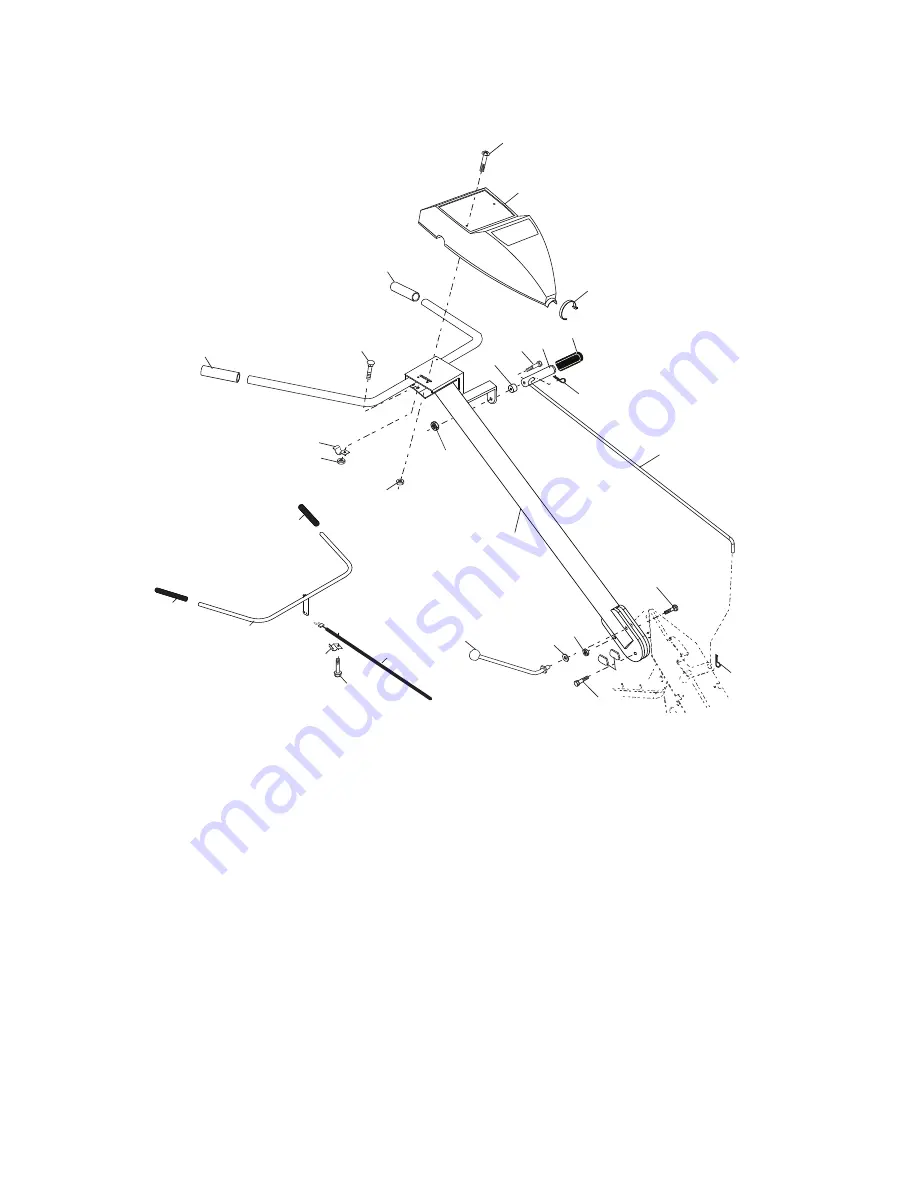

REPAIR PARTS

TILLER - - MODEL NUMBER DRT900LS (96093001500), PRODUCT NUMBER 960 93 00-15

HANDLE ASSEMBLY

KEY PART

NO. NO.

DESCRIPTION

21

532 18 11-27 Handle

23

532 08 67-77 Screw, Hex Washer SLT #10-24 x .50

24

532 00 94-84 Clip

26

532 15 92-31 Cable, Clutch

27

873 90 04-00 Nut, Hex Flange 1/4-20 unc

29

873 73 10-00 Nut, Keps #10-24 unc

30

532 10 41-64 Tie, Cable

31

532 15 06-96 Bolt, Pivot

33

872 14 04-04 Bolt, Carriage 1/4-20 unc x 1/2

37

532 10 26-04 Grip, Bar, Control

41

532 10 27-44 Clamp, Bar, Control

KEY PART

NO. NO.

DESCRIPTION

2

532 42 76-43 Grip, Handle

4

532 15 92-28 Bar Assembly, Control

6

532 18 06-85 Panel, Control

8

871 19 10-08 Screw, Truss Hd. #10-24 unc x 1/2

10

532 12 47-97 Grip, Handle

11

532 12 47-88 Clip, Hairpin

12

532 08 13-28 Bolt, Shoulder

13

532 18 74-97 Handle, Shift

14

532 10 93-13 Grommet, Rubber

15

532 10 93-37 Rod, Shift

16

872 11 06-08 Bolt, Carriage 3/8-16 x 1 Gr. 5

17

532 10 92-29 Lock, Handle

18

873 68 06-00 Nut, Crownlock 3/8-16 unc

19

819 13 16-11 Washer 13/32 x 1 x 11 Ga.

20

532 10 92-28 Lever, Lock, Handle

NOTE:

All component dimensions given in U.S. inches.

1 inch = 25.4 mm

33

2

2

6

3

0

8

2

7

2

4

2

6

23

15

11

1

0

12

13

21

1

9

18

31

1

7

1

6

11

2

0

2

9

2

7

4

1

3

7

3

7

4

H

a

n

d

l

e_ass

y

_

33

1

4