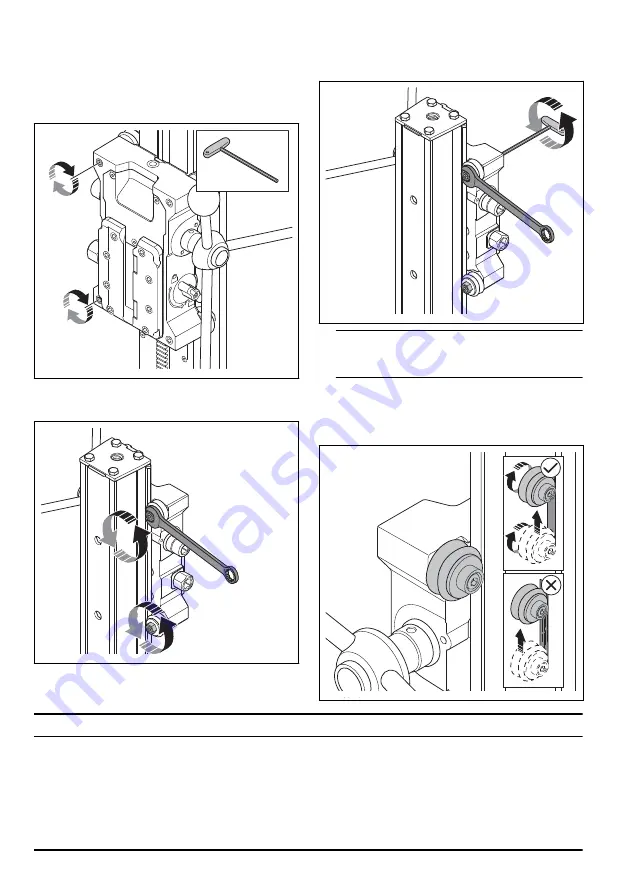

To adjust the drill motor carriage

If there is distance between the drill column and the drill

motor carriage, the drill motor carriage must be

adjusted.

1. Loosen the screws that hold the roller shafts.

6 mm

2. Adjust the roller shafts. Turn the screw

counterclockwise to move the guide wheels in the

direction of the drill column.

3. Lock the position of the guide wheel with a wrench.

Tighten the screw to lock the roller shaft with a hex

key.

Note: After you have tightened the roller shafts, they

must be possible to turn with the feed lever but not

by hand.

4. Use the feed lever to move the motor carriage up

and down. Make sure that the drill motor carriage

moves smoothly on the drill column. The roller shafts

must rotate and not move. If it is necessary, adjust

the roller shafts again.

Transportation and storage

Transportation and storage

• Safely attach the product during transportation to

prevent damage and accidents.

• The accessory transport wheels can be used to

transport the stand with mounted drill unit.

• Without transport wheels the drill unit needs to be

dismounted from the stand during transport as the

combined lifting weight is above 25 kg.

• Keep the product in a locked area to prevent access

for children or persons that are not approved.

24

922 - 002 - 06.03.2019