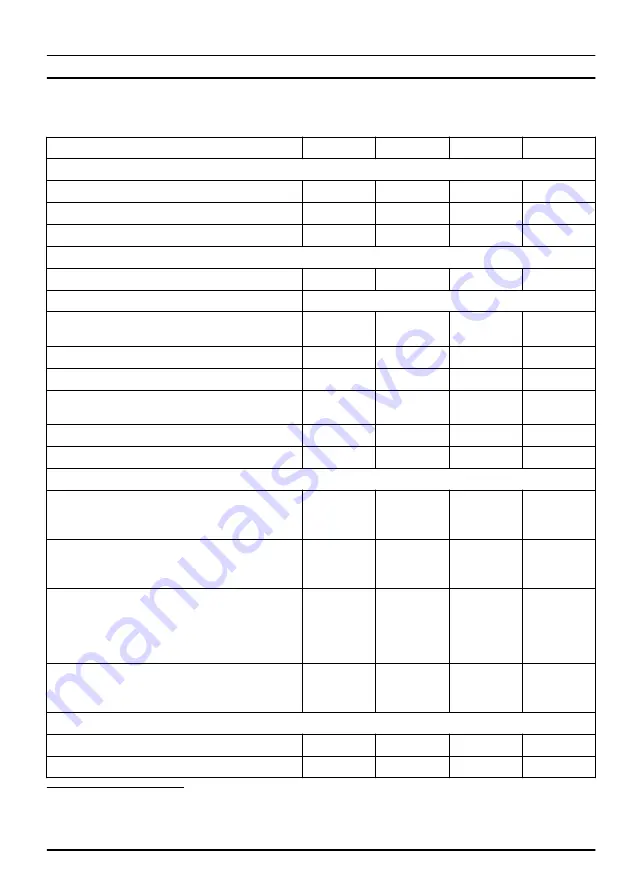

Technical data

Technical data

DXR 145

DXR 275

DXR 305

DXR 315

General

Rotation speed, rpm

6

6

6

6

Max. transport speed, km/h / mph

3/1.9

3/1.9

3/1.9

3/1.9

Max. slope angle, degrees

30

25

25

25

Hydraulic system

Volume hydraulic system, l/gal

40/10

50/13

50/13

50/13

Pump type

Load sensing axial piston with variable displacement.

Max. pump flow

2

, l/min or gal/min

0–52 or 0–14 0–75 or 0–20

0–85 or 0–

22.5

0–85 or 0–

22.5

Standard pressure, bar

200

200

200

200

Increased main pressure, bar

250

250

250

250

Pressure for caterpillar tracks tension and outriggers

retracted, 2,900 psi

130

200

200

200

Breaker pressure, bar

160

150

160

160

Telescopic arm pressure, bar

N/A

N/A

N/A

180

Motor

Motor power, kW/hp

18.5 (50 Hz)

18.5 (60 Hz)

24 (50 Hz)

24 (60 Hz)

27 (50 Hz)

27 (60 Hz)

27 (50 Hz)

27 (60 Hz)

Speed, rpm

2885 (50 Hz)

3500 (60 Hz)

1470 (50 Hz)

1775 (60 Hz)

1470 (50 Hz)

1775 (60 Hz)

1470 (50 Hz)

1775 (60 Hz)

Rated voltage, V

380–420 (50

Hz)

440–480 (60

Hz)

380–420 (50

Hz)

440–480 (60

Hz)

380–420 (50

Hz)

440–480 (60

Hz)

380–420 (50

Hz)

440–480 (60

Hz)

Rated current, A

32 (50 Hz)

30 (60 Hz)

46 (50 Hz)

39 (60 Hz)

52 (50 Hz)

44 (60 Hz)

52 (50 Hz)

44 (60 Hz)

Weight

Product weight without tool, kg/lbs

985/2172

1750/3858

1960/4320

2020/4453

Max. recommended tool weight, kg/lbs

3

200/441

310/683

310/683

310/683

2

Maximum pump flow and system pressure cannot be used at the same time. It can cause overload of the mo-

tor. 60 Hz has limited displacement.

3

Maximum recommended tool weight is the total weight of tool and maximum load.

1401 - 002 - 15.10.2021

107