• Replace worn or missing signs and decals.

• Do not use a product that is defective. Do the safety

checks, maintenance and the servicing as given in

this manual. All other maintenance work must be

done by an approved service agent.

• Make sure you have necessary training to do

maintenance.

• Use lifting equipment to lift heavy product parts and

to keep them in a stable position during

maintenance. Lock product parts mechanically

before maintenance to prevent injury from moving

parts.

• If you go away from the product, do a lockout-tagout

procedure.

• Only approved servicing personnel are permitted to

do maintenance in the electrical system and the

hydraulic system.

• Do the maintenance to make sure that the product

on page 63

.

• Do not do the troubleshooting of hydraulic leakage

with your hands. Do the troubleshooting visually.

Operation

Introduction

WARNING:

Before you operate the

product, you must read and understand the

safety chapter.

To do before you operate the product

1. Read the operator's manual carefully and make sure

that you understand the instructions.

2. Put on necessary personal protective equipment.

Personal protective equipment on page 20

.

3. Use a remote control harness to keep your body in

correct position and prevent injury.

4. Make sure that no persons are in the work area.

5. Do daily maintenance. Refer to

schedule on page 63

.

6. Make sure that the product is not damaged.

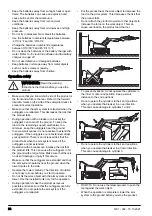

7. Install the tool on the product. Make sure that the

tool is correctly and safely installed. Refer to

install and remove the tools on the product on page

31

.

8. Make sure that the safety devices on the product are

not defective.

9. Put the product in the work area. Make sure that the

transportation of the product to and in the work area

is done safely and correctly. Refer to

on page 103

.

10. Make sure that the power cord and extension cable

are in good condition and not damaged.

11. Connect the product to a power source. Refer to

connect the product to a power source on page 30

.

12. Make sure that tools, such as screwdrivers or other

objects that are not used, are removed from the

product.

13. Make sure that the temperature of the hydraulic oil is

not less then 10°C/50°F. Refer to

.

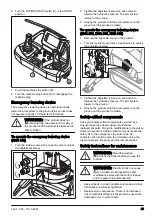

To connect the product to a power

source

WARNING:

Always connect the

product through an RCD with personal

protection. The RCD must trip at a ground

fault of 30 mA.

1. Make sure that the voltage is compatible with the

product and that the correct fuses are used. Refer to

Guide values for connection to a mains socket on

page 113

.

2. Connect the power plug of the product to the

extension cable.

3. Connect the extension cable to a mains outlet.

To let the product become warm

CAUTION:

Do not use maximum pump

pressure if the temperature of the hydraulic

oil is less than 10°C/50°F. You get maximum

pump pressure when you operate the

outriggers or the arm system to maximum

extension.

1. Start the product. Refer to

145) on page 52

and

275, DXR 305, DXR 315) on page 53

.

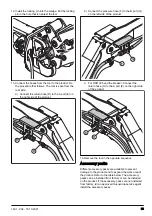

2. Extend the outriggers. Refer to

outriggers on page 61

.

3. First operate the caterpillar tracks slowly and then

more quickly.

4. Move the arm system slowly in all directions. Make

sure that there is no load on the arm system.

5. Do a check of the temperature of the hydraulic oil.

The optimal work temperatures are between 40°C/

104°F and 55°C/131°F.

6. If the temperature is not correct, do the procedure

again.

30

1401 - 002 - 15.10.2021