SAFETY INSTRUCTIONS

English

–

21

Education and training

New operators must be trained by experienced operators

with the capacity to use sound judgment when

supervising the work.

•

Practice stopping the machine and locating the stop

button quickly. Practice manenvering in different

directions, on a slope and different surfaces.

•

Test the machine’s stability under controlled

conditions. Practice rapid evacuation.

•

On completion of the training, the operator should be

properly acquainted with the machine’s limitations

with respect to reach, capacity and stability, and also

be able to maneuver the machine safely.

Maneuvering

General

•

If several machines are used at the same workplace

there is a risk of mixing up the remote controls.

Switch on the current to the remote control and the

machine. Press the horn to see which machine is

connected to the remote control. The machine will

beep and flash three times. Do not activate the remote

control before you have ensured that the correct

machine is being operated.

•

Wait until the remote control has been turned off and

the motor has stopped before you enter into the

machine’s risk area.

•

Never leave the machine unsupervised with the motor

running.

•

The machine can overturn during work. During

operation the machine must be positioned as level as

possible and the outriggers must be fully extended.

•

In some cases it can be difficult to determine which

end of the machine is the front and which is the rear.

Look at the direction markings on the sides of the

machine’s tracks to avoid incorrect operation.

•

When work is finished, operate the arm to rest against

the ground before turning off the machine.

Outriggers/dozer blade

•

When the outriggers/dozer blades are raised, the arm

should be contracted to minimize risk of the machine

toppling over.

•

The machine’s outriggers/dozer blade can lift from the

ground, especially when working with the hydraulic

breaker or bucket. The higher the machine is lifted, the

greater load the rest of the support function is exerted

to.

•

The risk of the machine overturning or landing with

great force on the outriggers/dozer blades is greater

when working with the hydraulic breaker in case of

strike through. Take this risk into account and institute

appropriate safety measures to avoid any personal

injury or mechanical damage.

Rotation function

•

If there is a breakdown in the machine’s rotation

mechanism the machine’s upper part may rotate

freely, potentially causing personal injury or

mechanical damage. Keep your distance.

•

The machine is most stable when working directly

forwards or backwards. When the machine’s upper

part rotates to the side, the outriggers should be down

and the arm system maneuvered so that it is as close

to the ground as possible.

•

In some cases it can be difficult to predict the direction

of rotation. Operate the turning motion carefully until

you have apprehended the direction of rotation.

Arm system

•

Do not use the arm system and the rotation function

for striking, demolishing or scraping.

•

Do not operate the arm with the machine’s outriggers/

dozer blade raised. Outriggers/dozer blades give

stability and reduce the risk of the machine

overturning.

•

When the arm system’s reach is being used, the load

increases as does the risk of tipping. Position the

machine as close to the working object as possible.

•

Do not secure the machine to fixed objects, e.g. walls,

to increase the force on the working object. Both the

machine and the tool can be subject to overloading.

•

Do not work with the machine’s cylinders in the inner

or outer end positions to avoid overloading. Leave a

few centimeters to the maximum position. The

hydraulic oil then has a greater capacity to alleviate

impacts and vibrations.

•

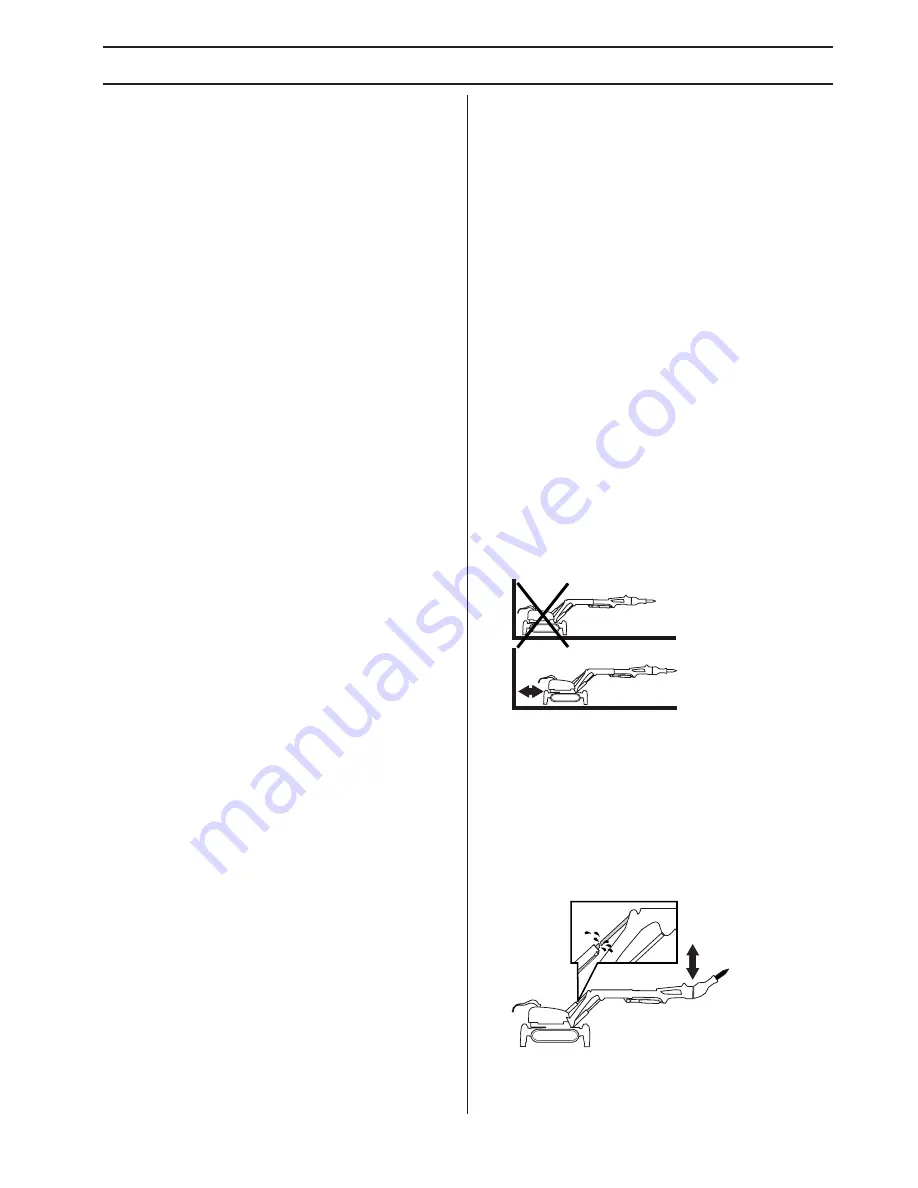

There are two working positions that put a lot of strain

on individual cylinders.

Cylinders 1 and 2 are in their outer positions and the

hammer is working in the upward direction. Never

operate the cylinders to their end positions.

Summary of Contents for DXR-310

Page 75: ...English 75 TECHNICAL DATA Range and transport diagram DXR250 4483 176 5 2020 79 5 4815 189 5 ...

Page 77: ...English 77 TECHNICAL DATA DXR270 4483 176 1986 78 4849 191 1435 56 ...

Page 79: ...English 79 TECHNICAL DATA DXR300 4868 192 2368 93 5231 206 1818 72 ...

Page 81: ...English 81 TECHNICAL DATA DXR310 5182 204 2129 84 2678 105 5549 218 ...

Page 84: ...1158619 27 z Z 78 z Z 78 2016 12 19 US Original instructions ...