TOOLS

32 – English

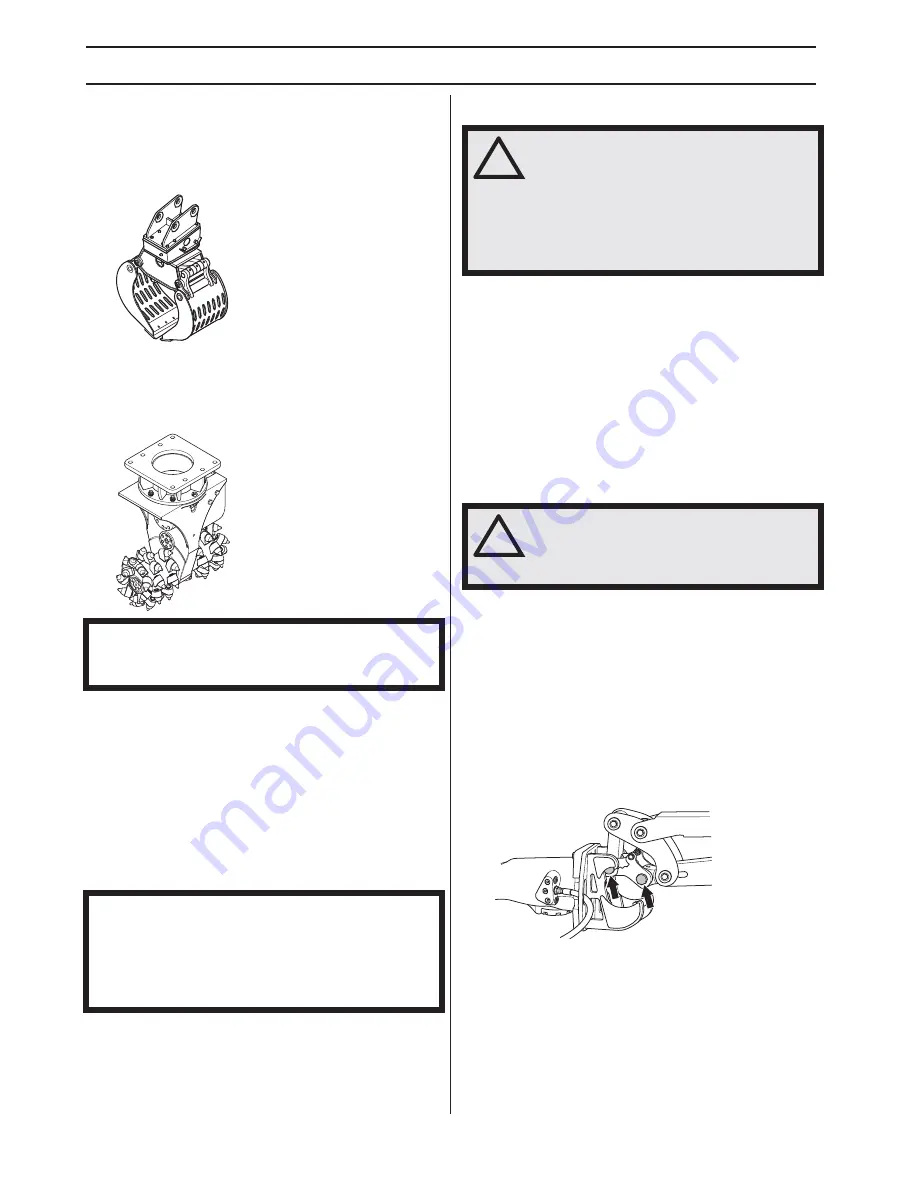

Grapple MG200

The grippers are intended for demolishing wooden

structures and brick walls, sorting and loading work. It is

not intended to pull/demolish beams, stays and walls.

Neither is it intended to hammer/hack or transport loads.

Drum cutter DC200

The drum cutter is designed to demolish and excavate by

means of milling. It is not intended for any other material

than rock, concrete, asphalt, frozen soil and ice.

External tool

External hydraulic tools can be connected to the machine.

External tool is activated from the service menu. See

instructions in the section "Settings".

Work mode

In the work menu you can choose to work with either a

breaker or a concrete crusher. The steel shears (others)

can be activated from the Work menu. See instructions in

the section "Settings".

Changing tools

Cleaning

Prevent dirt from entering the hydraulic system by:

•

Wiping dirt off the couplings before assembling or

dismantling.

•

Placing dust guards on the machine’s hydraulic

couplings when no tool is mounted.

•

Ensuring that the tool’s hoses are always connected

together when the tool is not connected to the

machine.

Assembly

•

Ensure that the machine is situated on a stable

surface with the outriggers down.

•

Position the tool with the holder facing the machine at

a suitable distance, not too close to the machine.

•

Ensure that the tool is turned the right way round.

Viewed from behind, the pressure connection of the

tool should be connected on the left side (B port) and

the return hose on the right side (A port).

•

Direct the tool holder so that it grips the tool. Tighten

the tool by raising the arm system and manoeuvring

cylinder 4 in.

NOTICE! The drum cutter requires the additional

Tool

Drain Kit

installed on the DXR because of the leakage

oil line.

NOTICE! There is a risk of damage to the machine if, for

example, the work pressure is delivered to a single-

acting tool’s return side, or if the machine’s or the

remote control’s settings are not correct for the tool in

question. There is more information about the remote

control’s settings in the 'Control system” section.

!

CAUTION! Changing tools may mean that

the operator has to be within the

machine’s risk area. Ensure that nobody

unintentionally starts the machine while

the tool is being changed. Keep a sharp

watch on the machine and be prepared to

turn it off. Guard hands and feet against

crushing.

!

CAUTION! Ensure that the tool is

correctly and securely fitted. If a tool

unexpectedly comes loose it can cause

personal injury.

Summary of Contents for DXR-310

Page 75: ...English 75 TECHNICAL DATA Range and transport diagram DXR250 4483 176 5 2020 79 5 4815 189 5 ...

Page 77: ...English 77 TECHNICAL DATA DXR270 4483 176 1986 78 4849 191 1435 56 ...

Page 79: ...English 79 TECHNICAL DATA DXR300 4868 192 2368 93 5231 206 1818 72 ...

Page 81: ...English 81 TECHNICAL DATA DXR310 5182 204 2129 84 2678 105 5549 218 ...

Page 84: ...1158619 27 z Z 78 z Z 78 2016 12 19 US Original instructions ...